-

Your shopping cart is empty!

Currently, motorized machines and especially excavators are an indispensable part in the field of civil, industrial and irrigation construction. In the market with many famous machine manufacturers such as Hitachi excavators, Catterpillar excavators, Kobelco excavators,... Besides, it would be remiss not to mention Komatsu crawler excavator PC600-8R1.

Komatsu crawer excavator PC600-8R1

Komatsu is the world's second largest supplier of construction and mining equipment, after Caterpillar. However, Komatsu has a larger market share than Caterpillar in some regions such as Japan and China. The company currently has many factories and branches in Japan, Asia, America and Europe and is still planning to continue to expand.

Komatsu excavator brand originated from Japan, appeared on the market since 1917. It can be said that this is one of the world's leading brands of excavators, currently competing fiercely with rivals. as big as Hitachi or Catterpillar. Komatsu excavator is considered as a machine with high durability, good working performance and common use. Perhaps that is also the reason why Vietnam and other countries around the world are very fond of the Komatsu line.

Komatsu excavators are specially designed for heavy duty applications. With a powerful engine, sturdy boom and bucket design, bearing iron material ensures workability and productivity in all cases. Along with compact structure and superior features, the company's machine can be widely applied such as: bridge construction, road construction, construction work in residential areas. The machine has many working modes with different engine speed and hydraulic system pressure to meet different conditions. In the fuel-saving mode, the machine still works effectively, in the heavy-duty mode, the machine can operate with the largest capacity, helping the digging and lifting force of the machine can be increased many times.

Below is the detailed product information of Komatsu crawler excavator PC600-8R1:

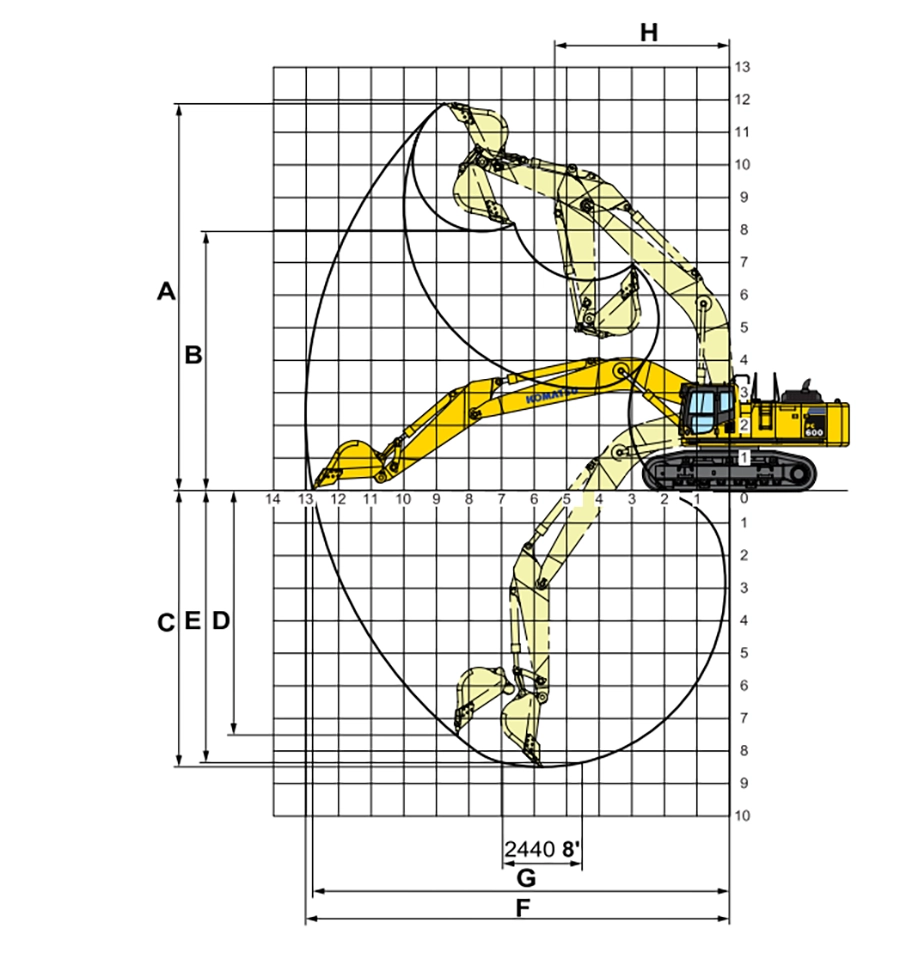

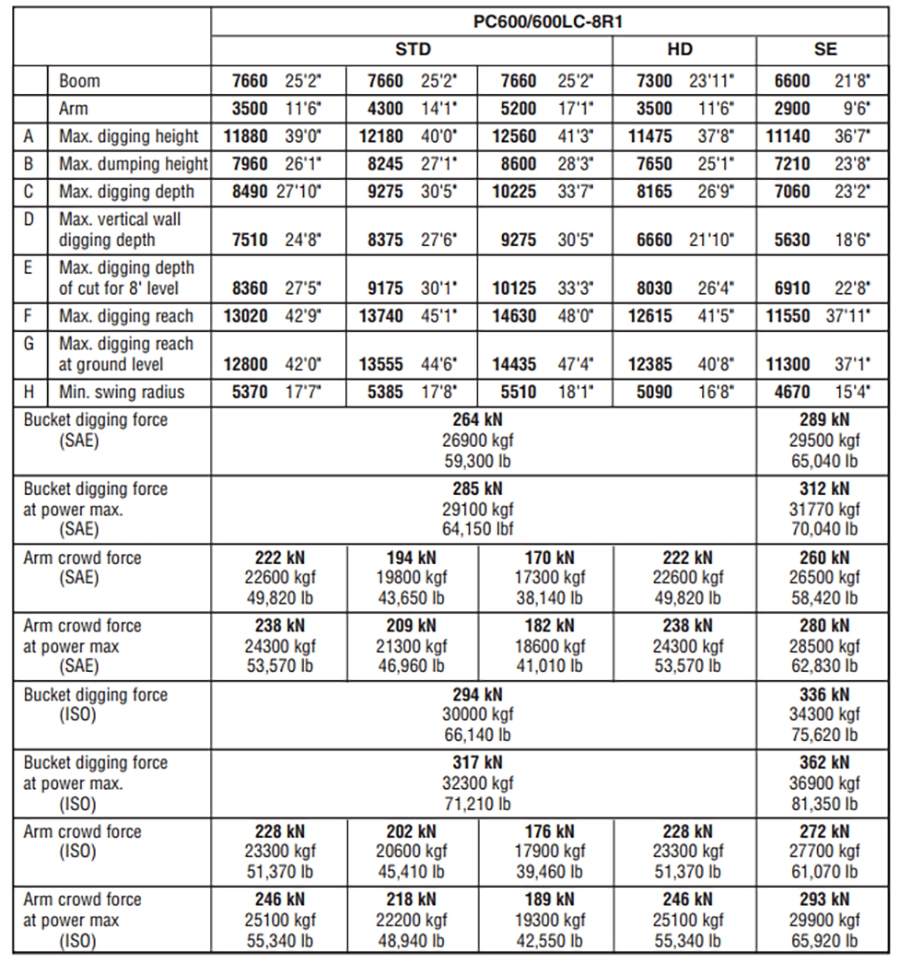

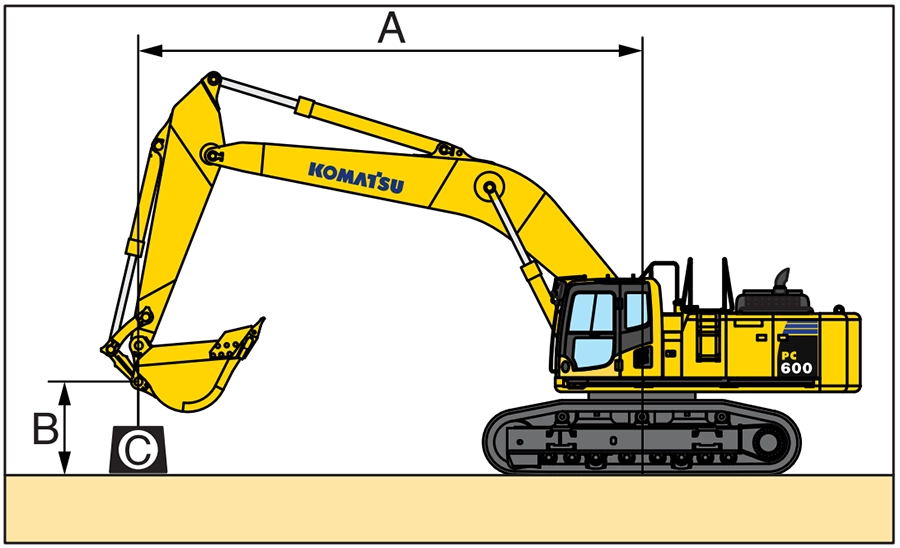

| WORKING RANGE | ||

|

||

|

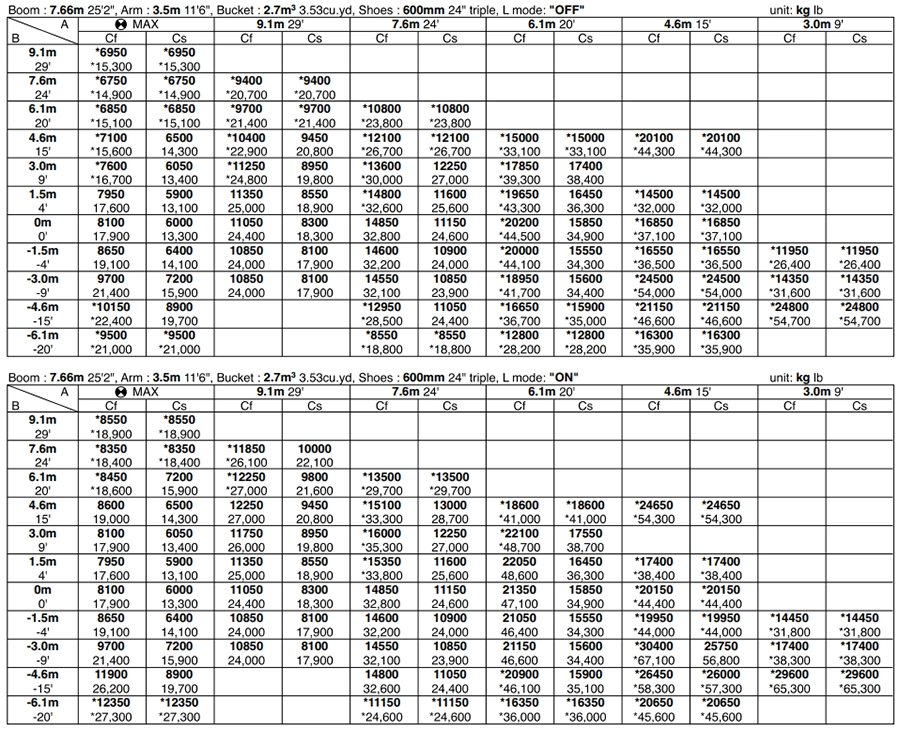

| LIFTING CAPACITY WITH LIFTING MODE

A: Reach from swing center B: Bucket hook height C: Lifting capacity Cf: Rating over front Cs: Rating over side Rating at maximum reach |

|

|

| * Load is limited by hydraulic capacity rather than tipping. Ratings are based on SAE J1097. Rated loads do not exceed 87% of hydraulic lift capacity or 75% of tipping load |

| SPECIFICATIONS | ||

| ENGINE | ||

| Model | Komatsu SAA6D140E-5 | |

| Type | Water-cooled, 4-cycle, direct injection | |

| Aspiration | Turbocharged, and air-to-air aftercooled | |

| Number of cylinders | 6 | |

| Horsepower | ||

| SAE J1995, Gross | kW | 323 kW (433 HP) at 1 800 rpm |

| ISO 9249 / SAE J1349, Net | kW | 320 kW (429 HP) at 1 800 rpm |

| Fan drive method for radiator cooling | Mechanical | |

| Piston displacement | l | 15.24 |

| Bore x Stroke | mm | 140 x 165 |

| Governor | All-speed control, electronic | |

| HYDRAULIC SYSTEM | ||

| Type | Open-center load-sensing system | |

| Number of selectable working modes | 3 | |

| Main pump | Variable-capacity piston pumps | |

| Pumps for | Boom, arm, bucket, swing, and travel circuits | |

| Maximum flow | l/min | 2 x 410 |

| Supply for control circuit | Variable-capacity piston pump | |

| Hydraulic motors | ||

| Travel | 2 x axial piston motor with parking brake | |

| Swing | 1 x axial piston motor with swing holding brake | |

| Relief valve setting | ||

| Implement circuits | ||

| Backhoe | MPa (kgf/cm2) | 31.9 (325) |

| Loading shove | MPa (kgf/cm2) | 29.4 (300) |

| Swing circuit | MPa (kgf/cm2) | 25.5 (260) |

| Travel circuit | MPa (kgf/cm2) | 34.3 (350) |

| Pilot circuit | MPa (kgf/cm2) | 2.9 (30) |

| UNDERCARRIAGE | ||

| Center frame | X-frame | |

| Track frame | Box-section | |

| Seal of track | Sealed track | |

| Track adjuster | Hydraulic | |

| Number of shoes (Each side) | 49 | |

| Number of carrier rollers (Each side) | 3 | |

| Number of track rollers (Each side) | 8 | |

| DRIVES AND BRAKES | ||

| Steering control | Two levers with pedals | |

| Drive method | Hydrostatic | |

| Travel motor | Axial piston motor, in-shoe design | |

| Maximum drawbar pull | kN (kg) | 415 (42 300) |

| Gradeability | % (°) | 70 ( 35 ) |

| Maximum travel speed | km/h |

High: 4.9 Low: 3 |

| Service brake | Hydraulic lock | |

| Parking brake | Mechanical disc brake | |

| COOLANT AND LUBRICANT CAPACITY (REFILLING) | ||

| Fuel tank | l | 880 |

| Coolant | l | 58 |

| Engine | l | 40 |

| Final drive (Each side) | l | 10 |

| Swing drive | l | 2 x 13 |

| Hydraulic tank | l | 360 |

| SWING SYSTEM | ||

| Drive method | Hydrostatic | |

| Swing reduction | Planetary gear | |

| Swing circle lubrication | Grease-bathed | |

| Service brake | Hydraulic lock | |

| Holding brake/Swing lock | Mechanical disc brake | |

| Swing speed | min-1 | 8.3 |

| HYDRAULIC CYLINDERS | |||||

| Number | Bore | Stroke | Rod Diameter | ||

| Boom | mm | 2 | 185 | 1 725 | 120 |

| Arm | |||||

| Std | mm | 1 | 200 | 2 045 | 140 |

| SE | mm | 1 | 200 | 2 045 | 140 |

| Bucket | |||||

| Std | mm | 1 | 185 | 1 425 | 130 |

| SE | mm | 1 | 185 | 1 610 | 130 |

| OPERATING WEIGHT (APPROXIMATE) | |||

| Shoe Type | Shoe | kg | kPa (kgf / cm2) |

| Triple grouser | 600 mm | 59 200 | 104.9 (1.07) |

| 750 mm | 60 000 | 85.3 (0.87) | |

| BACKHOE - Operating weight, including 7660 mm 25'2" boom, 3500 mm 11'6" arm, SAE heaped 2.7 m3 3.53 yd3 backhoe bucket, operator, lubricant, coolant, full fuel tank, and the standard equipment | |||

| Double grouser | 600 mm | 63 200 | 111.8 (1.14) |

| LOADING SHOVEL - Operating weight, including 4000 mm 13'1" boom, 3000 mm 9'10" arm, 4.0 m3 5.2 yd3 heaped bucket, operator, lubricants, coolant, full fuel tank and standard equipment | |||

| OPTIONS |

|

Komatsu Technology

Komatsu develops and produces all major components, such as engines, electronics and hydraulic components, in house. With this “Komatsu Technology” and adding customer feedback, Komatsu is achieving great advancements in technology. To achieve both high levels of productivity and economical performance, Komatsu has developed the main components with a total control system. The result is a new generation of high performance and environment-friendly excavators.

High Power Komatsu SAA6D140E Engine

Powerful turbocharged and air-to-air aftercooled Komatsu SAA6D140E-5 engine provides 320 kW 429 HP. This Komatsu SAA6D140E engine actualizes high-power to low fuel consumption with the optimum fuel injection by electronic heavy duty HPCR (High Pressure Common Rail) fuel injection system.

Electronically Controlled Variable Speed Fan Contributes to Low Fuel Consumption and Low Noise

The electronic control system sets the revolution speed of the cooling fan according to the coolant, hydraulic oil, and ambient temperature; effectively uses the engine output to prevent wasteful fuel consumption; and reduces noise during low-speed fan revolution.

Lower and Economical Fuel Consumption Using Economy Mode

Enables operator to set the Economy mode to four levels according to working conditions so that production requirement is achieved at the lowest fuel consumption.

Low Ambient Noise

Reduced noise by adoption of an electronically controlled variable speed fan drive, large hybrid fan and low-noise muffler.

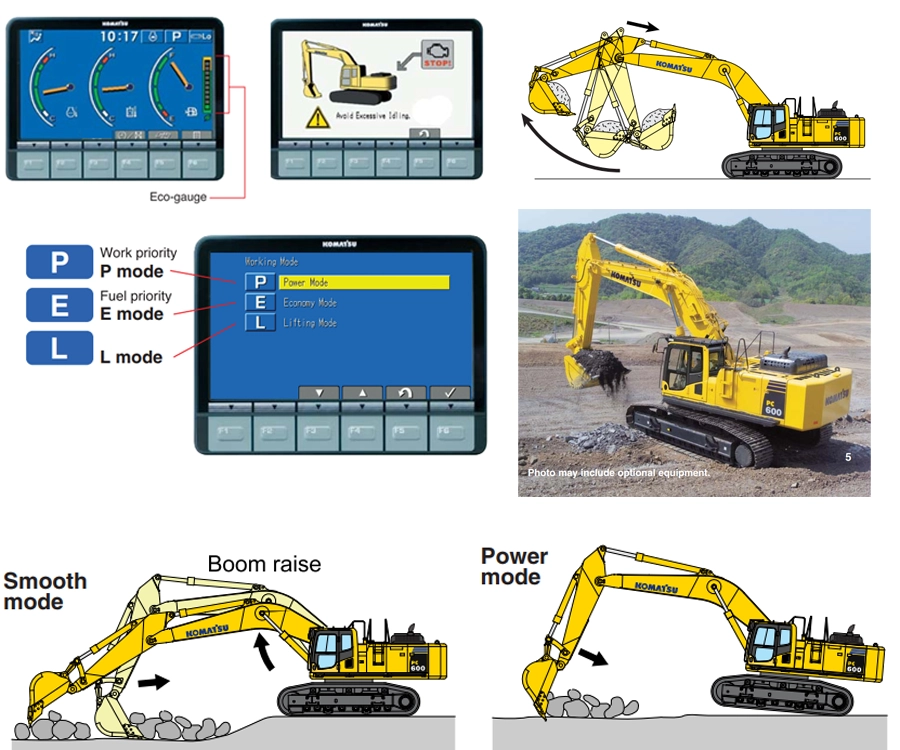

ECO Gauge that Assists Energy-saving Operations

Equipped with the ECO gauge that can be recognized at a glance on the right of the multifunction color monitor for environmentfriendly energy-saving operations. Allows focus on operation in the green range with reduced CO2 emissions and efficient fuel consumption.

Large Digging Force

With the addition of one-touch Power Max. function digging force is further increased. (8 seconds of operation)

- Maximum arm crowd force (ISO): 228 kN (23.3 tons) => 246 kN (25.1 tons) (with Power Max.)

- Maximum bucket digging force (ISO): 294 kN (30.0 tons) => 317 kN (32.3 tons) (with Power Max.)

*Measured with Power Max function, 3500 mm 11'6" arm and ISO rating

Work Equipment Speed Increased

Work equipment speed and arm speed of compound operation becomes greater with arm quick return circuit and arm regeneration circuit. Quick loading work is now accomplished.

Idling Caution

To prevent unnecessary fuel consumption, an idling caution is displayed on the monitor if the engine idles for 5 minutes or more

Auto Deceleration and Auto Idling System

Auto deceleration system is equipped to reduce fuel consumption and operating noise. Also, engine idling speed can be reduced on the monitor with the auto idling system.

Working Modes Selectable

P and E work modes are further improved.

- P mode: Power or work priority mode has low fuel consumption, but fast equipment speed and maximum production and power are maintained.

- E mode: Economy or fuel saving mode further reduces fuel consumption, but maintains the P-modelike work equipment speed for light duty work.

You can select Power or Economy modes using a one-touch button on the monitor panel depending on the workload

Two-mode Setting for Boom

Smooth mode provides easy operation for gathering blasted rock and scraping operations. When maximum digging force is needed, switch to power mode for more effective excavating.

Lifting Mode

Gives 17% more lifting force when needed for handling rock or heavy lifting applications.

Large Drawbar Pull and Steering Force

Since the machine has a large drawbar pull and a high steering force, it demonstrates excellent mobility even when it is on inclined sites.

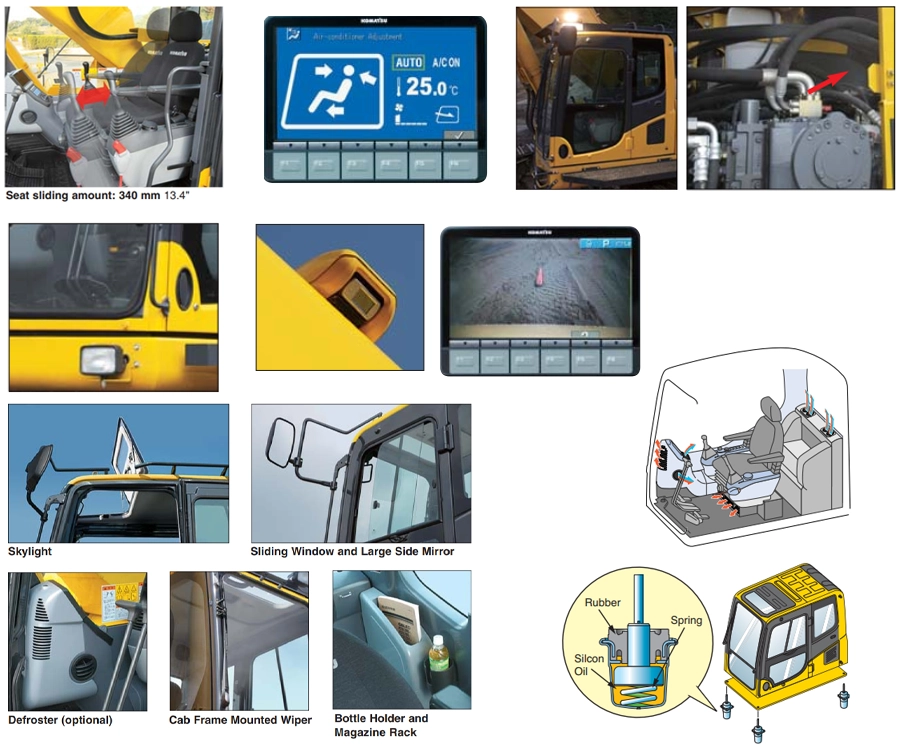

Wide Newly-designed Cab

Newly-designed wide spacious cab includes seat with reclining backrest. The seat height and longitudinal inclination are easily adjusted using a pull-up lever. You can set the appropriate operational position of the armrest and the console. The reclining seat further enables you to place it into the fully flat state with the headrest attached.

Low Noise Design Cab

The newly-designed cab is highly rigid and has excellent sound absorption ability. Thorough improvement of noise source reduction and use of low noise engine, hydraulic equipment, and air conditioner allows the operator to work in quiet condition.

Pressurized Cab

Optional air conditioner, air filter and a higher internal air pressure (+6.0 mm Aq +0.2"Aq) prevent external dust from entering the cab.

Multi-position Controls

The multi-position, PPC (proportional pressure control) levers allow the operator to work in comfort while maintaining precise control. A doubleslide mechanism allows the seat and control levers to move together or independently, allowing the operator to position the controls for maximum productivity and comfort.

Low Vibration with Cab Damper Mounting

PC600-8R1 uses viscous damper mounts for the cab that incorporates longer stroke and the addition of a spring. The cab damper mounting combined with high rigidity deck aids vibration reduction at the operator’s seat.

Automatic Air Conditioner (optional)

Enables you to easily and precisely set cab atmosphere with the instruments on the large LCD. The bi-level control function keeps the operator's head and feet cool and warm respectively. This improved air flow function keeps the inside of the cab comfortable throughout the year. Defroster function keeps front glass clear.

Step Light with Timer (optional) provides light for about one minute to allow the operator to get off the machine safely

Pump/engine Room Partition prevents oil from spraying on the engine if a hydraulic hose should burst.

Thermal and Fan Guards are placed around high-temperature parts of the engine and fan drive.

Anti-slip Plates

Spiked plates on working areas provide anti-slip performance.

Horn Interconnected with Warning Light (optional) gives visual and audible notice of the excavator’s operation when activated

Rear View Monitoring System (optional)

The operator can view the rear of the machine with a color monitor screen

OPG top guard (optional)

OPG top guard Level 2 (by ISO 10262) capable with optional bolt-on top guard

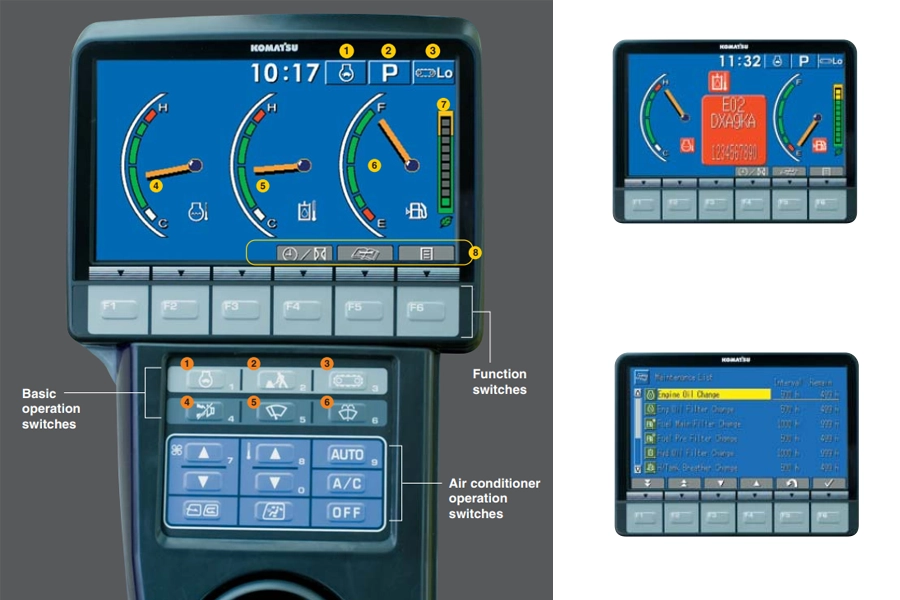

Large LCD Color Monitor

A large user-friendly color monitor enables safe, accurate and smooth work. Improved screen visibility is achieved by the use of LCD that can easily be read at various angles and lighting conditions. Simple and easy to operate switches. Industry first function keys facilitate multi-function operations. Displays data in 12 languages to globally support operators around the world.

Indicators

1. Auto-decelerator

2. Working mode

3. Travel speed

4. Engine water temperature gauge

5. Hydraulic oil temperature gauge

6. Fuel gauge

7. ECO gauge

8. Function switches menu

Basic operation switches

1. Auto-decelerator

2. Working mode selector

3. Traveling selector

4. Buzzer cancel

5. Wiper

6. Windshield washer

Mode Selection

The multi-function color monitor has Power mode (two levels), Economy mode (four levels), and Lifting mode.

- P (P0, P1): Maximum production/power, fast cycle time.

- E (E0, E1, E2, E3): Good cycle time, good fuel economy.

- L: Hydraulic pressure isincreased 17%.

EMMS (Equipment Management Monitoring System) Monitor Function

Controller monitors engine oil level, coolant temperature, battery charge and air clogging, etc. If controller finds any abnormality, it is displayed on the LCD.

Maintenance Function

Monitor informs replacement time for oil and filters when the replacement interval is reached.

Trouble Data Memory Function

Monitor stores abnormalities for effective troubleshooting.

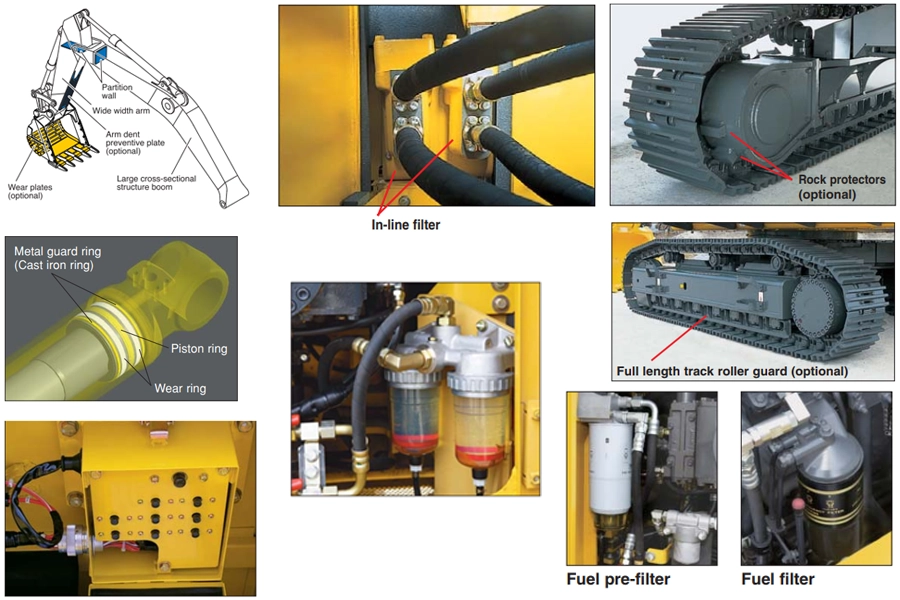

Strengthened Boom and Arm (optional)

Thanks to the large cross-sectional structure employing a high tensile strength steel with a thick plate, partition wall, etc., the boom and arm exhibit excellent durability and are highly resistant to bending and torsional stress.

Metal Guard Rings

Metal guard rings protect all the hydraulic cylinders and improve reliability.

Sturdy Undercarriage

The undercarriage is strengthened to provide excellent reliability and durability when working on rocky ground or blasted rock. Sturdy guards shield the travel motors and piping against damage from rocks. (Rock protectors are optional.)

Strengthened Revolving Frame Underguard

Guards the machine piping against being hit by rocks from below and prevents hydraulic components and the engine from being damaged.

High-pressure In-line Filtration

The PC600-8R1 has the most extensive filtration system available, providing inline filters as standard equipment. An inline filter in the outlet port of each main hydraulic pump reduces failures caused by contamination.

O-ring Face Seal

The hydraulic hose seal method has been changed from a conventional taper seal to an O-ring seal. This provides improved sealing performance during operation.

Frame Structure

The revolving frame mount and center frame mount on the swing circle are no welding structure so that force is transmitted directly to the thick plate of the frame without passing through any welding.

Fuel Pre-filter (with Water Separator)

Removes water and contaminants from fuel to enhance the fuel system reliability.

High Efficiency Fuel Filter

Fuel system reliability is even better with high efficiency fuel filter.

Heat-resistant Wiring

Heat-resistant wiring is used for the engine electric circuit and other major component circuit.

Water Separator

Removes water from the fuel and improves the reliability of fuel systems.

DT-type Connectors

DT-type connectors seal tight and have higher reliability.

Circuit Breaker

With circuit breaker, the machine can be easily restarted after repair

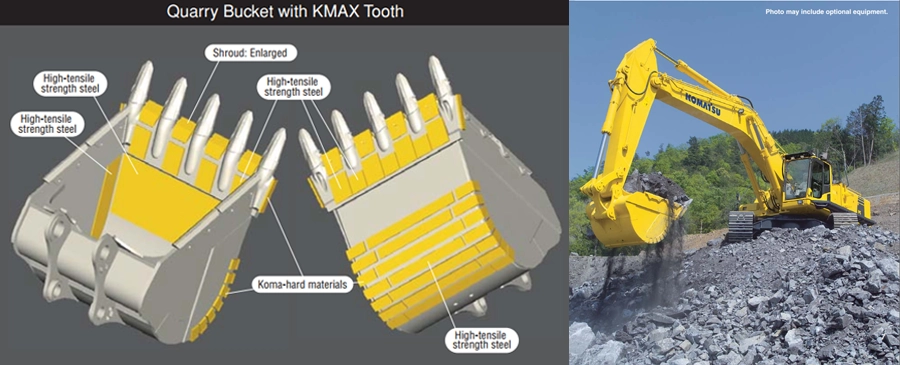

Strengthened Quarry Bucket Provides Outstanding Wear-resistance (optional)

The bucket for specific use in quarry is impact and wear resistant, providing high performance and long life. Koma-hard materials* provide excellent wear resistance. Combined with adoption of long-life KMAX tooth, durability of bucket is drastically enhanced.

* Koma-hard materials (KVX materials): Komatsu developed, wear-resistant, reinforced materials. Brinell hardness: 500 or more (180kgf/mm2 class). Features high wear-resistance and little quality change by the heat generated during rock loading, maintaining the hardness for a long term.

KMAX Tooth

- Unique bucket tooth shape for superior digging performance

- Long-term high sharpness

- Great penetration performance

- Hammerless, safe, and easy tooth replacement (Tooth replacement time: Half of the conventional machine).

Easy Checking and Maintenance of Engine

Engine check points are concentrated on one side of the machine to facilitate daily checks. Thermal guards are placed around high-temperature parts such as turbocharger.

Wide Catwalk

Easier, safer operator cab access and maintenance checks.

Electric Pump, Grease Gun with Indicator (optional)

Greasing is made easy with the electric pump and grease gun with indicator.

Anti-slip Plates

Spiked plates provided on top of the machine cab maintains anti-slip performance for a prolonged period.

Easy Cleaning of Cooling Unit

Reverse-rotation function of the hydraulic driven fan simplies cleaning out the cooling unit.

Steps Connected to the Machine Cab

Steps allows access from left hand catwalk to top of machine for engine check and maintenance.

Easy Detachable Radiator and Oil Cooler

Engine hood opens fully to facilitate removal and installation of the radiator and oil cooler. The hood can be opened vertically by changing the position of the torsion bar.

Long-life Oil, Filter

Uses high-performance filtering materials and long-life oil. Extends the oil and filter replacement interval.

- Engine oil and Engine oil filter every 500 hours

- Hydraulic oil every 5000 hours

- Hydraulic oil filter every 1000 hours

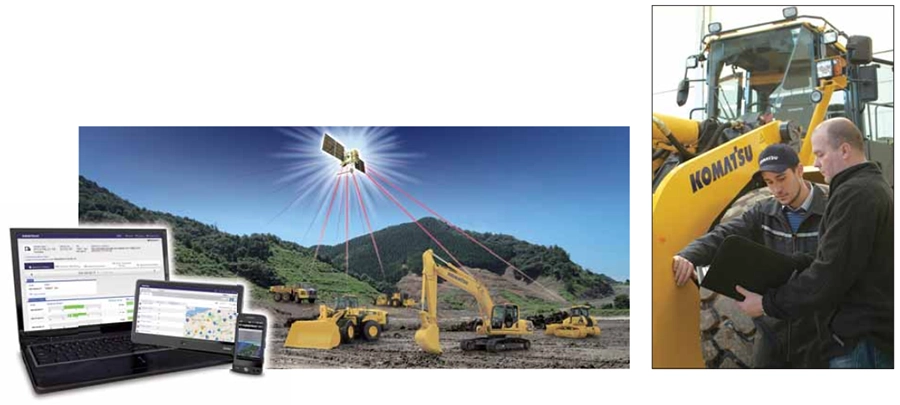

Komatsu Total Support

To keep your machine available and minimize operation cost when you need it, Komatsu Distributor is ready to provide a variety of supports before and after procuring the machine.

Technical support

Komatsu product support service (Technical support) is designed to help customer. Komatsu Distributor offers a variety of effective services to show how much Komatsu is dedicated to the maintenance and support of Komatsu machine.

- Preventive Maintenance (PM) clinic

- Oil & Wear analysis program

- Undercarriage inspection service, etc.

Fleet recommendation

Komatsu Distributor can study the customer’s job site and provide the most optimum fleet recommendation with detailed information to meet all of your application needs when you are considering to buy new machines or replace the existing ones from Komatsu.

Product support

Komatsu Distributor gives the proactive support and secures the quality of the machinery that will be delivered.

Parts availability

Komatsu Distributor is available for emergency inquiry by the customers for genuine, quality guaranteed Komatsu parts.

Repair & maintenance service

Komatsu Distributor offers quality repair and maintenance service to the customer, utilizing and promoting Komatsu developed programs.

Komatsu Reman (Remanufactured) components

Komatsu Reman products are the result of the implementation of the Komatsu global policy which establishes and agrees to reduce the owning, operating and total Life Cycle Costs (LCC) to Komatsu’s customer through high quality, prompt delivery and competitively priced in own remanufactured products (QDC).

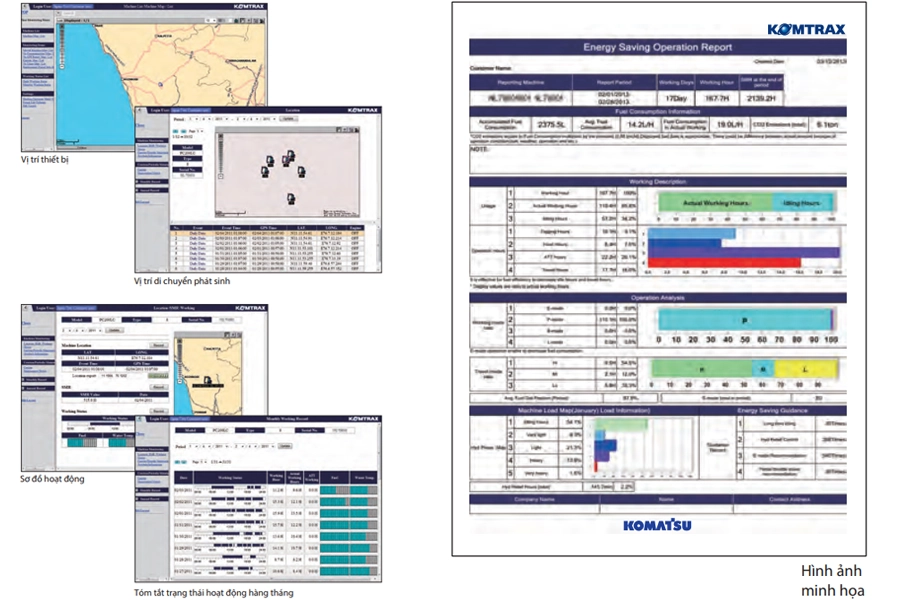

KOMTRAX

The Komatsu remote monitoring and management technology provides insightful data about your equipment and fleet in user-friendly format.

Energy Saving Operation Report

KOMTRAX delivers the energy-saving operation report based on the operating information such as fuel consumption, load summary and idling time, which helps you efficiently run a business.

Equipment Management Support

Through the web application, a variety of search parameters are available to quickly find information about specific machines based on key factors. Moreover, KOMTRAX finds out machines with problems from your fleet and shows you through an optimal interface.

Optimal Strategy for Efficient Work

The detailed information that KOMTRAX puts at your fingertips helps you manage your fleet conveniently on the web anytime, anywhere. It gives you the power to make better daily and long-term strategic decisions.

Trính dẫn: "Komatsu máy đào bao nhiêu vậy"

Tags: KOMATSU PC600 8R1, KOMATSU PC450 8R, KOMATSU PC300 8M0, komatsu PC200 8M0, komatsu pc350 8, komatsu pc350 6, Komatsu 350, KOMATSU PC350 10, Komatsu PC210 6, Komatsu PC78US 6, komatsu 75 3, excavator for sale, excavator hire, excavator Komatsu, excavator hitachi, sany excavator, wheel excavator for sale, bucket wheel excavator, power wheel excavator, largest bucket wheel excavator, bucket wheel excavator price, volvo wheel excavator, bucket wheel excavator for sale, wheeled excavator, wheeled excavator for sale, wheel bucket excavator, wheel type excavator, wheeled excavator volvo, wheeled excavator hitachi

Trính dẫn: "Komatsu máy đào bao nhiêu vậy"