EHB50

| Brand | Everdigm |

| Type | Hydraulic Breaker |

| Model | EHB50 |

| Working height | 4,010 kg |

| Applicable carrier weigh | 40 - 70 ton |

| Tool shank diameter | 180 mm |

| Country of Manufacture | Korea |

| Location | Viet Nam |

| Contact | 0985 048 030 |

| Dowload Brochure | ATT_BreakerEng |

| Brand | Everdigm |

| Type | Hydraulic Breaker |

| Model | EHB50 |

| Working height | 4,010 kg |

| Applicable carrier weigh | 40 - 70 ton |

| Tool shank diameter | 180 mm |

| Country of Manufacture | Korea |

| Location | Viet Nam |

| Contact | 0985 048 030 |

| Dowload Brochure | ATT_BreakerEng |

| Item | Unit | EHB50 | |

| Working weight | kg | 4,010 | |

| Required oil flow | lpm | 230 - 330 | |

| Operating pressure | bar | 165 - 185 | |

| Blow frequenc | Low speed mode | bpm | 250 - 370 |

| High speed mode | bpm | 350 - 500 | |

| Low speed mode | joule | 10,400 | |

| High speed mode | joule | 7,900 | |

| Tool shank diameter | mm | 180 | |

| Applicable carrier weigh | tonne | 40 - 70 | |

Note:

1) Total Weight including standard tool, standard mounting adapter and spacers but excluding hysraulic hoses, fittings and mounting pins.

2) Measured in accordance with the certified test procedure which complies with the AEM(formerly CIMA)tool energy rating for hydraulic breakers. Materials and specifications are subject to change without prior notice

With the goal to be a total solution provider for tool carriers, EVERDIGM attachments have grown into most reliable attachment manufacturer in Korea and worldwide distribution partners in 70 countries. Meanwhile, company has continuously verified the excellent quality by achieving ISO9001, ISO14001, CE and AEM tool energy rating which realized by high qualified R&D team, efficiency-integrated manufacturing system and goal oriented professional people. With full ranged product line of hydraulic breaker, multiprocessor, pulverizer, compactor, multipurpose grab, quick coupler and other attachments, EVERDIGM attachments fulfill the maximum productivity and durability to construction and demolition job site.

|

Why develop the tool energy rating? Assessing and comparing hydraulic breakers have never been easier or more accurate than the Tool Energy developed by the Mounted Breaker Manufacture Bureau (MBMB) of the AEM. The AEM is the U.S. based international trade group serving the business needs of construction equipment manufacturers and construction services providers. The AEM Tool Energy Rating is accepted by hydraulic breaker manufacturers from Finland, France, Germany, Italy, Japan, Korea, Sweden and the United States. EVERDIGM Corp. has been accredited to self-certify tool energy ratings obtained through test process complying with "AEM Measuring Guide." |

AEM Tool Energy Rating test bench simulate actual working condition under controlled situations. Each breaker is tested 25 times while AEM certified observer is monitoring test procedure. Then the each impact energy measured by strain gauges on tool bit is recorded on computer. To be compared with other AEM-MBMB certified breakers all variables like flow, pressure and etc, which affect actual impact energy throughout the tests, are averaged to one specific value. By having this test bench, all breakers manufactured complying with AEM-Tool Energy rating give customers more practical and accurate standard to select breaker. Only breakers that have been tested and certified under AEM regulation can display AEM-MBMB decal.

|

|

|

| Test unit installed on impact base connected with strain gauge in tool bit and flow and pressure gauge on hoses port of cylinder | Static calibration test stand for correct measurement | Control console with monitoring panel Power pack to replicate actual situation |

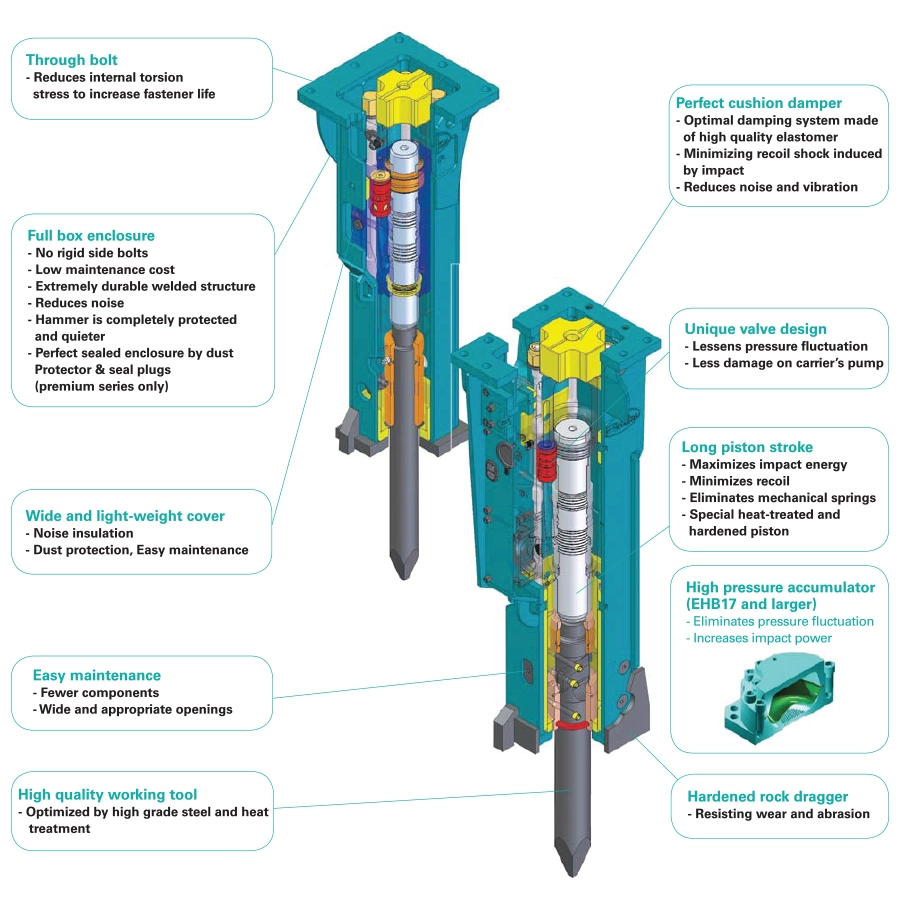

- Pressurized nitrogen gas is the main power source, to operate with less demand on the carrier's hudraulic system.

- Control blow frequency adjusting to hardness of rock

- Auto dispense of lubricating paste, each time hammer is operating.

- High temperature & high grade chisel

- New type of composite 2 layered damper and wear plate have longer lifetime than conventional material. This gives longer maintenance invertal.

- Significantly reduces blank blow induced failures.

- Reduces vibration induced hose failure.

- Around one-third as its competitor, around 30 to 90 items depending on model

- Easy maintenance

- Dealers need fewer spare parts in inventory

- Easy to rebuild

- Allowing hammer submerged in water from EHB05 & bigger models.

- Enable to utilize centralized auto grease system

-Jigsaw shaped main bracket design achieves better resilience from external force. This ensure sound and long lasting body structure.

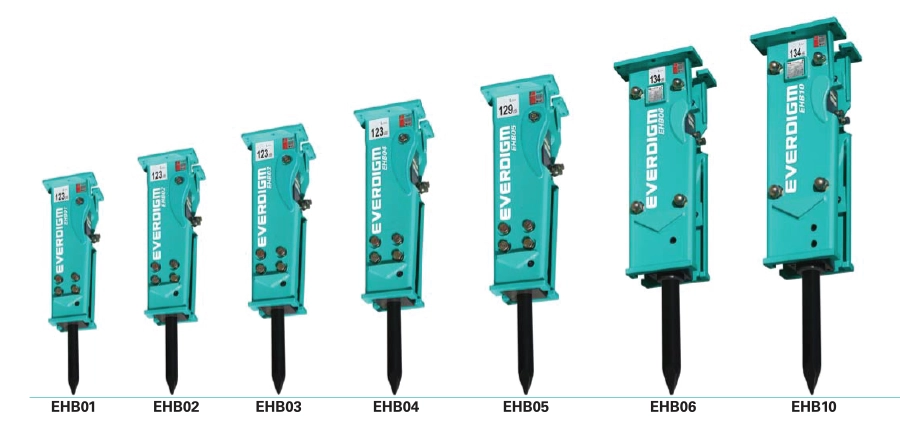

Prime series are silenced type breakers that developed for environment and human health according to international trend of noise restriction. By wearing a hard boots of reinforced rock dragger and bracket,prime series provides much innovative durability with maximum power than ever. The benefits of this series are dual speed control system, hard boots(EHB13 and larger), anti blank blow system, auto stop & auto start and single high pressure acumulator(EHB17 and larger).

Skidsteer series Skidsteer series are developed for skidsteer loader to meet the market requirement of higher impact energy and optimal performance.

Backhoe series are developed for backhoe loader to meet the required design for transportation.

Tags: búa phá đá, búa đá, phụ kiện phá đá, everdigm, ehb, everdigm ehb, everdigm ehb30, búa phá đá cũ, búa phá đá mới, mua búa phá đá ở đâu, mua búa phá đá cũ, búa phá đá qua sử dụng, everdigm cũ, everdigm mới

Contact

Contact

Contact