-

Your shopping cart is empty!

The Doosan Group - founded in 1896 and headquartered in Seoul, South Korea - is one of the fastest-growing companies in the world:

- With more than 37,500 employees in 38 countries, we are a major player in a variety of industries worldwide.

- A global leader in the Infrastructure Support Business (ISB), with 56 subsidiaries and 3,700 distributors worldwide.

- Dramatic growth over the past two decades, with an annual Doosan Group revenue rising from €2.4 billion in 1998 to €12.8 billion in 2016

- Doosan Infracore: Among the world's Top 5 manufacturers of construction equipment

- Doosan Bobcat: A leading company in the design, manufacture, marketing, distribution and service of small equipment and attachments for construction, agriculture, and landscaping. Leading position in the global compact equipment market. N° 1 in North America for SSL, CTL and MEX.

- Doosan Heavy Industries & Construction: World N° 1 in desalination plant construction, World N° 1 in heat recovery steam generator market, World N° 1 in mould & tool steel, World N° 3 in crankshafts

- Doosan Engineering & Construction: A pioneering leader in construction of residential and public buildings, civil works and industrial facilities. World N° 1 chemical process equipment products

Creating construction equipment for over 40 years. For over 40 years, we've been building a global production and business network to become one of the world’s foremost construction equipment manufacturers.

A solid partner, close to you. A truly global player in every respect, we have large-scale factories, sales subsidiaries and dealers all over the world.

To ensure the highest trade-in and residual values, our parts and service support professionals maintain the performance, productivity and reliability that you expect of our products throughout their lifetime.

As your local specialist, your dealer ensures that you receive the maximum benefit from our integrated package. Plan ahead to ensure the success of your equipment!

- Articulated Dump Trucks

- Doosan Wheel Loaders

- Doosan Wheeled Excavators

- Doosan Mini Excavators

- Doosan Crawler Excavators.

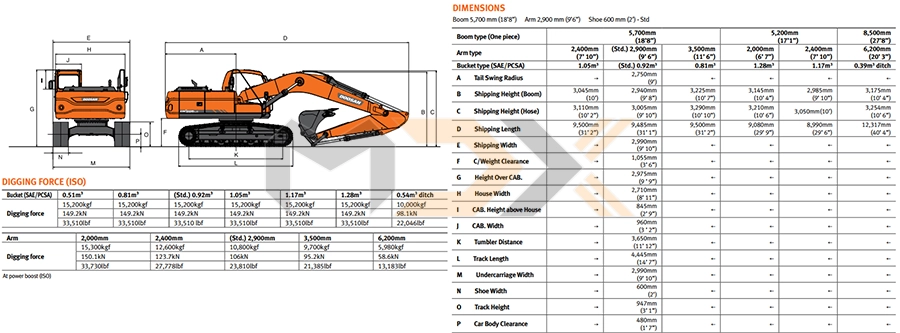

| DEMENSIONS | |

|

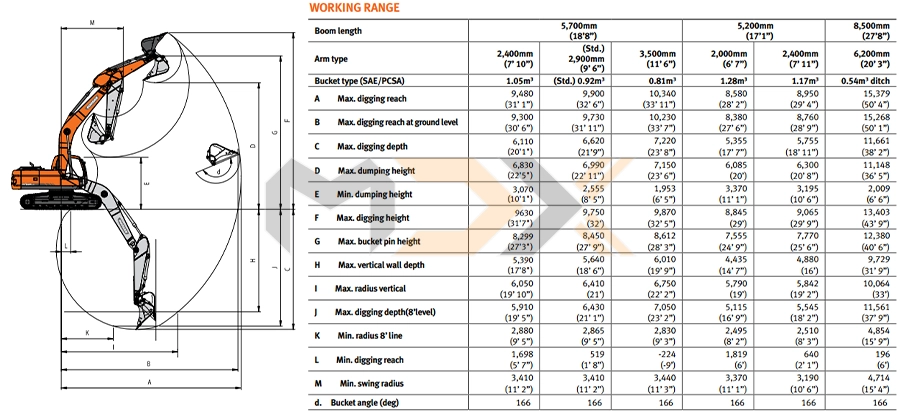

| WORKING RANGES | |

|

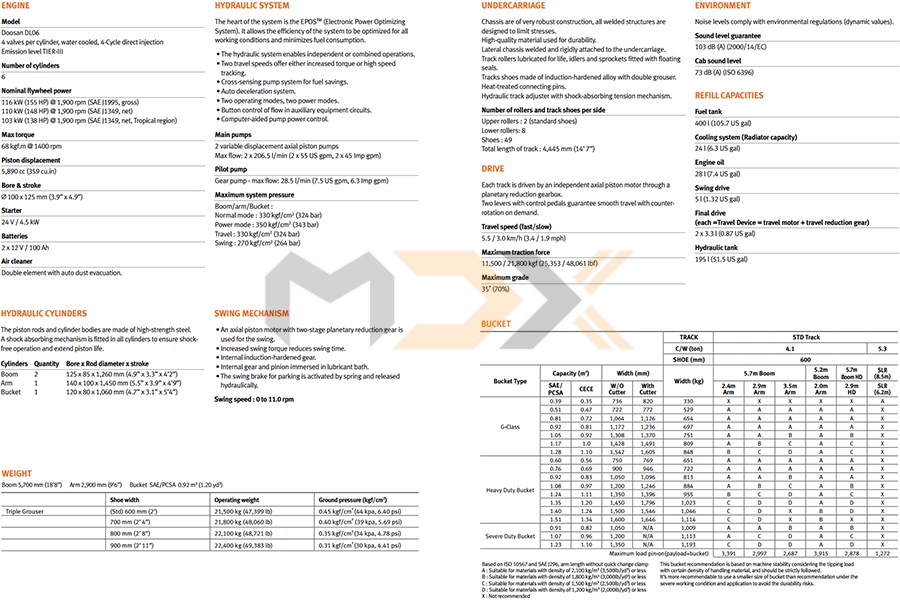

| TECHNICAL SPECIFICATIONS | |

|

The new DX225LC hydraulic excavator has all the advantages of the previous model, and now offers additional added value to the operator. The key phrase used during the development of the DX225LC was “giving optimum value to the end user.

1. HEAVY-DUTY SPECIFICATION TO GUARANTEE MACHINE UPTIME

- Heavy duty boom & arm

- 3 stages fuel filtering system with larger capacity water-separator.

- Dry type pre air cleaner added to Air filtering system has made engine more adaptable to dusty area.

2. ENHANCE EASY ACCESS TO ALL COMPARTMENT

- In-house built engine is easy to fix due to simple structure

- Filter locations are easily accessible at ground level

3. BEST WORk EFFICIENCY

- Provide 3 working mode

- Operator can select proper working mode for best productivity.

7 INCH MONITOR

- New, user-friendly LCD color monitor with full access to machine settings and maintenance data.

- Rear camera(optional) and large side mirrors enhance operator's visibility

TROPICAL HYDRAULIC OIL (ISO VG 68)

- Maintain best performance by keeping optimum viscosity in tropical region.

ADVANCED FRONT BUSH

- EM bushing (Enhanced Macro-surface)

- Pocket & Dimple surface pattern: Optimized greasing & Trap foreign object

- Wear resistant solid lubricant coating: Noise free & enhanced anti-seizure property

- 30% longer life time than steel bush

ADVANCED H-CLASS BUCKET

- Doosan new H-class bucket designed for higher productivity.

- Newly designed side cutter and abrasion resistant steel increase bucket solidity.

HEAVY-DUTY FRONT

- Reinforced castings and forged steel pivot points and reinforced heavy-duty arm and boom to withstand high-impact materials.

- To better protect the base of the arm, reinforced bars have been added and the arm center and end boss have been strengthened.

ROPS CERTIFIED CABIN (OPTIONAL)

- One of the most spacious cabs in the market, with low noise & vibration levels and excellent all-round visibility.

- Fully adjustable suspension seat, air conditioning with climate control as standard.

PRE CLEANER

- Rotor type dry pre-cleaner an standard (Donaldson Top Spin 5")

- Separate more than 99% of particles of 20 micron and above particles.

WATER SEPARATOR

- Large capacity of additional fuel water separator filters water in fuel and enhance engine’s durability

ADVANCED UNDERCARRIAGE

Strengthen Sprocket structure and tooth - Structure to minimize incoming debris.

Performance is what it’s all about; Doosan delivers what you need and then some. For decades, Doosan machines have proven themselves on thousands of jobsites around the world. Our long carriage (LC) design provides superior stability and optimizes working width for superior performance in heavy digging and lifting operations. Powerful hydraulic, arm and bucket forces with horsepower to spare help you get the job done quickly and efficiently

DOOSAN ENGINE (DL06)

At the heart of the hydraulic excavator is the new “Common Rail” DOOSAN DL06 engine. It is combined with the new e-EPOS electronic control system, for optimum power and fuel saving. The new engine produces 155 hp(116 kw/157 PS) at only 1,900 rpm, and more torque, due to its careful design combined with the ues of common rail injection and 4 valves per cylinder. These features help optimize combustion

and minimize pollution through reduced Nox & particulate emissions. Increased torque allows efficient use of the power of the hydraulic system. Faster working cycles increase productivity. Increased torque means the excavator is able to move more easily. Energy efficiency reduces fuel consumption

- Faster working cycles increase productivity.

- Increased torque means the excavator is able to move more easily.

- Energy efficiency reduces fuel consumption.

HYDRAULIC PUMP

The Main pump has a capacity of 2x206.5l/min reducing cycle time while a high capacity gear pump improves pilot line efficiency.

TRAVEL DEVICE

In house travel device provides simple internal structure and increases efficiency of the performance. Thicker sprocket minimizes incoming debris and provides higher durability.

SWING DRIVE

Shocks during rotation are minimized, while increased torque is available to ensure faster working cycles. \

EXCAVATOR CONTROL

Improved Excavator control by New EPOSTM system. The brains of the hydraulic excavator, the EPOSTM (Electronic Power Optimizing system), have been improved, through a CAN (Controller Area Network) communication link, these units are now perfectly synchronised.

HEAVY DUTY BOOM & ARM BOOM AS STANDARD

- Center boss Plate: size increased 40%.

- Boom End bracket: Single piece of casting type.

- Arm bottom Plate:Increase plate thickness 20%

- Arm side Plate: Increase plate thickness 15%

- Arm back Plate:Equipped add. Reinforced bar.

- Heavy Duty bucket:Enhanced design new bucket

- Boom Plate: Increase boom foot height and decrease width, increase plate thickness 15%.

ADVANCED PIN-BUSH AND DISK / SHIM TECHNOLOGY

Pocket & Dimple surface pattern: Optimized greasing & Trap foreign object.

- Wear resistant solid lubricant coating: Noise free & enhanced anti-seizureproperty.

- Ultra-hard wear-resistant disc: Increase the wear resistance and the service intervals.

TRACKS

The chain is composed of self-lubricating sealed links isolated from all external contamination. The tracks are locked by mechanically bolted pins.

INTEGRATED TRACK SPRING AND IDLER

The track spring and the idler have been joined directly to achieve high durability and improved maintenance convenience.

HEAVY DUTY & FIXED TRACK (OPTIONAL)

1. Idler Bracket: Thick & Wide strip to avoid bracket bending

2. Track Under Cover Plate: Reinforced track under cover (3.2T 4.5T), Reinforced mounting

3. Track Motor Cover: (Out) Add bolt head guard, (In) Reinforced motor cover mounting bolt using steel rib.

RELIEF CUTOFF

The pump continues to supply flow even when the maximum pressure on the system is reached due to severe working environments and large workloads. Relief cutoff technology of DX225LC prevents transfer of unnecessary flow to maintain powerful working level at the maximum value while reducing consumption of fuel.

OPTIMIZED LEVER CONTROL & AUTO IDLE

When operator takes a break and leaves the control joystick fixed, both of the engine and the pump are kept in standby mode and prevents unnecessary fuel consumption.

PUMP MATCHING TECHNOLOGY

Engine & pump matching, the new technology of Doosan, fully resolves problems; low respones time of the system, unnecessary fuel consumption. Matching response time between pump and engine efficiently reduces unnecessary fuel consumption as well as exhaust fumes.

The DX225LC is designed to provide you with the best possible working conditions. The pressurised cab and its spacious interior offer a fully adjustable, suspension seat. Comfortably seated, you have easy access to several storage compartments and a clear all-round view of the worksite. Noise and vibration levels have been reduced, while air conditioning and automatic climate control allow you to keep working for hours on end without feeling tired.

MONITOR

3 power modes for maximum efficiency: Power mode, Standand mode,Economy mode

3 work modes to suit your application: 1-way mode, 2-way mode, Digging mode.

CONTROL LEVER

Very precise control of the equipment increases versatility, safety and facilitates tricky operations requiring great precision. Levelling operations and the movement of lifted loads in particular are made easier and safer. DOOSAN designed the DX225LC by putting the operator at the center of the development goals. The result is significant ergonomic value that improves the efficiency and safety of the operator. More space, better visibility, air conditioning, a very comfortable seat. These are all elements that ensure that the operator can work for hours and hours in excellent conditions.

AIR SUSPENSION SEAT (OPTIONAL)

Equipped with various functions of adjustment forth and back and, and lumbar support, it reduces the vibration of equipment transmitted during work in an effective way. Also for considering winter working environment, Seat warmer functions equipped.

Short maintenance operations at long intervals increase the availability of the equipment on site. DOOSAN has developed the DX225LC with a view to high profitability for the user.

ENGINE OIL FILTER

The engine oil filter offers a high level of filtration allowing the oil change interval to be increased to 500 hours. It is easy to access and is positioned to avoid contaminating the surrounding environment.

PC MONITORING (DMS)

A PC monitoring function enables connection to the EPOSTM system, allowing various parameters to be checked during maintenance, such as pump pressures, engine rotation speed, etc. and these can be stored and printed for subsequent analysis.

AIR CLEANER

The large capacity forced air cleaner removes over 99% of airborne particles, reducing the risk of engine contamination and making the cleaning and cartridge change intervals greater.

PRE CLEANER

Install rotor type pre-cleaner (Donaldson Top Spin 5”). So filtering efficiency 20% increased

WATER SEPARATOR

High efficiency and large capacity water separator protect the engine by removing most moisture from the fuel (additional water separator as strandard)

CENTRALIZED GREASE INLETS FOR EASY MAINTENANCE

The arm grease inlets are grouped for easy access.

EASY MAINTENANCE

Access to the various radiators is very easy, making cleaning easier. Access to the various parts of the engine is from the top and via side panels.

HYDRAULIC OIL RETURN FILTER

The protection of the hydraulic system is made more effective by the use of glass fiber filter technology in the main oil return filter. This means that with more than 99.5% of foreign particles filtered out, the oil change interval is increased.

Telematics Service terminal is installed to machine / connected to EPOSTM

GPS, EPOSTM data is sent to designated server by GSM, Satellite telecommunication

Doosan, Dealer, Customer can easily monitor the GPS, EPOSTM data from Core Telematics Service web.

TELEMATICS SERVICE BENEFITS

Customer: Improve work efficiency (Timely and preventive service, Improve operator’s skills by comparing work pattern, Manage fleet more effectively).

Dealer: Better service for customers (Provide better quality of service, Maintain machine value, Better understanding of market needs).

Doosan: Responsive to customer’s voice (Utilize quality-related field data, Apply customer’s usage profile to developing new machine).

Doosan provides fast and precise worldwide delivery of genuine Doosan parts through its global PDC (parts distribution center) network.

The global network of the GPDC (Global Parts Distribution Center) maximizes its supply rate by making sure that each center is stockpiled with all the critical parts required for businesses in its area. The network also minimizes the time and costs required for parts delivery by positioning PDCs close to major markets around the world. Doosan PDCs communicate with customers in their time zone, informing them that they are open for operation, and deliver parts to them as early as possible.

PDCs had been set up as shown below, including Mother PDC in Ansan, Korea. The seven other PDCs include one in China (Yantai), one in the USA (Chicago), one in Brazil (Campinas), two in Europe (Germany and the UK), one in the Middle East (Dubai), and one in Asia (Singapore).

Tags: Doosan DX225LC, Doosan DX140W 5, Doosan DX530LC 7, Doosan DX490LC 7, Doosan DX350LC 7, Doosan DX300LC 7, Doosan DX255LC 5, Doosan DX235LC 5, Doosan DX180LC 5, Doosan DX160LC 5 HT, Doosan DX140LCR 5, doosan DX140LC 5, excavator for sale, excavator hire, excavator Komatsu, excavator hitachi, sany excavator, wheel excavator for sale, bucket wheel excavator, power wheel excavator, largest bucket wheel excavator, bucket wheel excavator price, volvo wheel excavator, bucket wheel excavator for sale, wheeled excavator, wheeled excavator for sale, wheel bucket excavator, wheel type excavator, wheeled excavator volvo, wheeled excavator hitachi