-

Your shopping cart is empty!

The Doosan Group - founded in 1896 and headquartered in Seoul, South Korea - is one of the fastest-growing companies in the world:

- With more than 37,500 employees in 38 countries, we are a major player in a variety of industries worldwide.

- A global leader in the Infrastructure Support Business (ISB), with 56 subsidiaries and 3,700 distributors worldwide.

- Dramatic growth over the past two decades, with an annual Doosan Group revenue rising from €2.4 billion in 1998 to €12.8 billion in 2016

- Doosan Infracore: Among the world's Top 5 manufacturers of construction equipment

- Doosan Bobcat: A leading company in the design, manufacture, marketing, distribution and service of small equipment and attachments for construction, agriculture, and landscaping. Leading position in the global compact equipment market. N° 1 in North America for SSL, CTL and MEX.

- Doosan Heavy Industries & Construction: World N° 1 in desalination plant construction, World N° 1 in heat recovery steam generator market, World N° 1 in mould & tool steel, World N° 3 in crankshafts

- Doosan Engineering & Construction: A pioneering leader in construction of residential and public buildings, civil works and industrial facilities. World N° 1 chemical process equipment products

Creating construction equipment for over 40 years. For over 40 years, we've been building a global production and business network to become one of the world’s foremost construction equipment manufacturers.

A solid partner, close to you. A truly global player in every respect, we have large-scale factories, sales subsidiaries and dealers all over the world.

To ensure the highest trade-in and residual values, our parts and service support professionals maintain the performance, productivity and reliability that you expect of our products throughout their lifetime.

As your local specialist, your dealer ensures that you receive the maximum benefit from our integrated package. Plan ahead to ensure the success of your equipment!

- Articulated Dump Trucks

- Doosan Wheel Loaders

- Doosan Wheeled Excavators

- Doosan Mini Excavators

- Doosan Crawler Excavators.

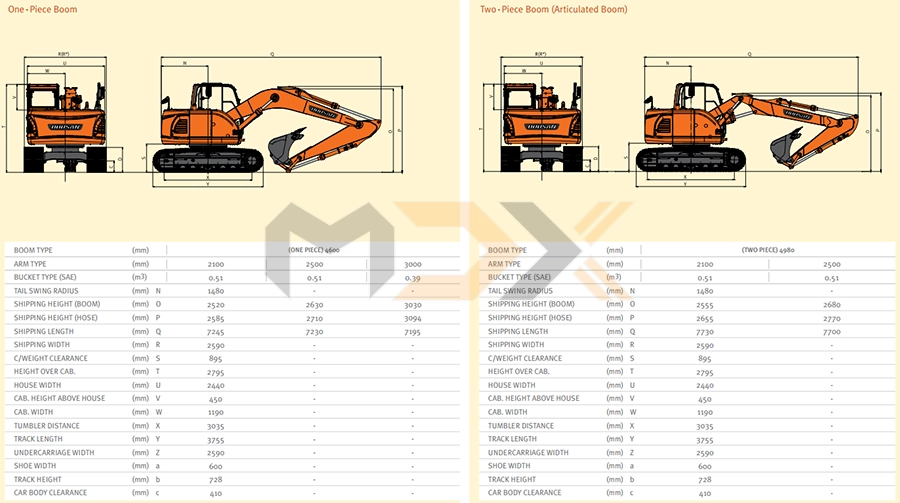

| DEMENSIONS | |

|

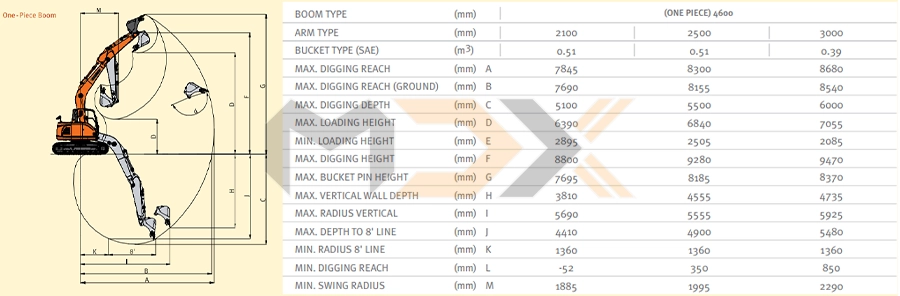

| WORKING RANGES | |

|

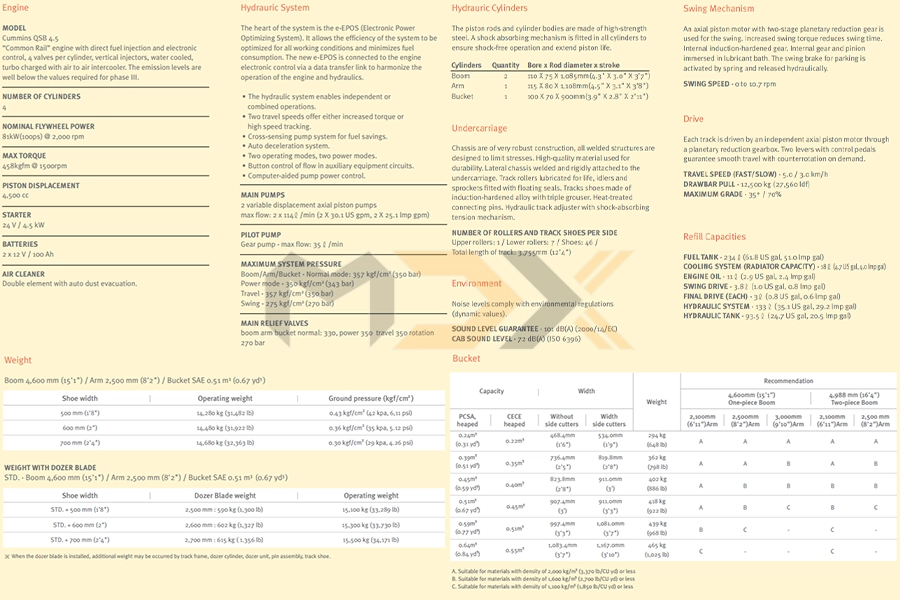

| TECHNICAL SPECIFICATIONS | |

|

Novel Increased production and improved fuel economy is attributed to the electronic optimization of the hydraulic system and the new generation DOOSAN engine (Tier Stage ). Improved ergonomics increases comfort and excellent all round visibility ensuring a safe and pleasant working environment. Improved reliability is achieved through the use of high performance materials combined with new methods of structural stress analysis,and leads to increased component life expectancy,thus reducing running costs. Reduced maintenance increases the availability and reduces operating costs of the excavator.

The performance of the DX140LCR has a direct effect on its productivity.Its new "Common Rail" engine and new e-EPOS controlled hydraulic system have combined to create an unbeatable hydraulic excavator, with a cost/performance ratio that makes the DX140LCR even more appealing.

Reduced Tail Swing Radius

“It can be easily used in the city and tight locations, due to reducing the tail swing radius up to 33%".

Machinery industry

Accumulated experience and business know-how established through the years as a leader of Korea’s machinery industry.

Swing Drive

Shocks during rotation are minimized,while increased torque is available to ensure rapid cycles.

Hydraulic Pump

The Main pump has a capacity of 2x114 /min(@2,000 rpm)reducing cycle time while a high capacity gear pump improves pilot line efficiency.

The work rate of the hydraulic excavator is directly linked to the performace of its operator. DOOSAN designed the DX140LCR by putting the operator at the center of the development goals. The result is significant ergonomic value that improves the efficiency and safety of the operator.

Control panel

More space,better visibility,air conditioning,a very comfortable seat... These are all elements that ensure the operator can work for hours and hours in excellent conditions.

Choice of operating modes

Working mode: Digging mode:for general excavation, loading,lifting...Trenching mode:swing priority for trench work, canal digging, embankments...

Power mode: Standard:uses 85%engine power for all work. Power: uses 100% engine power for heavy work.

Control lever

Very precise control of the equipment increases versatility, safety and facilitates tricky operations requiring great precision. Leveling operations and the movement of suspended loads are made easier and safer.

Rear Camera

The reliability of a product contributes to its overall lifetime operating costs.

Strengthened Boom

The shape of the boom has been optimized by finite elements design, allowing uniform load distribution throughout the structure.

Arm Assembly

In the arm assembly greater strength has been gained by using cast elements and reinforcement around the bosses to give increased life.

Doosan uses computer- assisted design techniques,highly durable materials and a quality engineered structure. Our research and development engineers test all product under the most extreme conditions. Durability,reliability and product longevity are Doosan's top priorities.

Bushing

A highly lubricated metal is used for the boom pivot in order to increase the lifetime and extend the greasing intervals to 250 hours.

Ultra-hard wear-resistant disc

New materials have been used in order to increase the wear resistance and to increase the service intervals.

X-chassis

The X-chassis frame section has been designed using finite element and 3-dimensional computer simulation.

Integrated Track Spring and Idler

The track spring and the idler have been joined directly to achieve high durability and improved maintenance convenience.

Tracks

The chain is composed of self-lubricating sealed links isolated from all external contamination.

DOOSAN has developed the DX140LCR profitability with end-user in mined. Easy maintenance operations at long intervals increase the availability of the equipment on site.

Easy maintenance

Easy access to the various radiators and coolers makes cleaning easier. Access to the various parts of the eng ine is from the top and via side panels.

Engine oil filter

The engine oil filter offers a high level of filtration allowing the oil change interval to be increased to 500 hours.

Hydraulic oil return filter

The protection of the hydraulic system is more effective, using glass fiber filter technology in the main oil return filter.

Air cleaner

The large capacity forced air cleaner removes over 99% of airborn eparticles, reducing the risk of engine contamination and making the cleaning and cartridge change intervals greater.

Fuel pre-filter

High efficiency fuel filtration is attained by the use of multiple filters, including a fuel pre-filter fitted with a water separator that removes most moisture from the fuel.

PC Monitoring (DMS)

A PC monitoring function enables connection to the e-EPOS system, allowing various parameters to be checked during maintenance

Convenient Fuse Box

The fuse box is conveniently located in a section of the storage compartment behind the operator's seat providing a clean environment and easy access.

Centralized grease inlets for easy maintenance

The arm grease inlets are grouped for easy access.

Tags: Doosan DX140W 5, Doosan DX530LC 7, Doosan DX490LC 7, Doosan DX350LC 7, Doosan DX300LC 7, Doosan DX255LC 5, Doosan DX235LC 5, Doosan DX180LC 5, Doosan DX160LC 5 HT, Doosan DX140LCR 5, doosan DX140LC 5, excavator for sale, excavator hire, excavator Komatsu, excavator hitachi, sany excavator, wheel excavator for sale, bucket wheel excavator, power wheel excavator, largest bucket wheel excavator, bucket wheel excavator price, volvo wheel excavator, bucket wheel excavator for sale, wheeled excavator, wheeled excavator for sale, wheel bucket excavator, wheel type excavator, wheeled excavator volvo, wheeled excavator hitachi