| Model | Big Multiplex Ski |

| Type | Ultrasonic Sensor |

| Suitable for | Vogele "Dash 3" asphalt paver |

| Maximum Length | 13m |

| Manufacture | Voegele |

| Country of Origin | Germany |

| Location | Vietnam |

| Contact | 0985 048 030 |

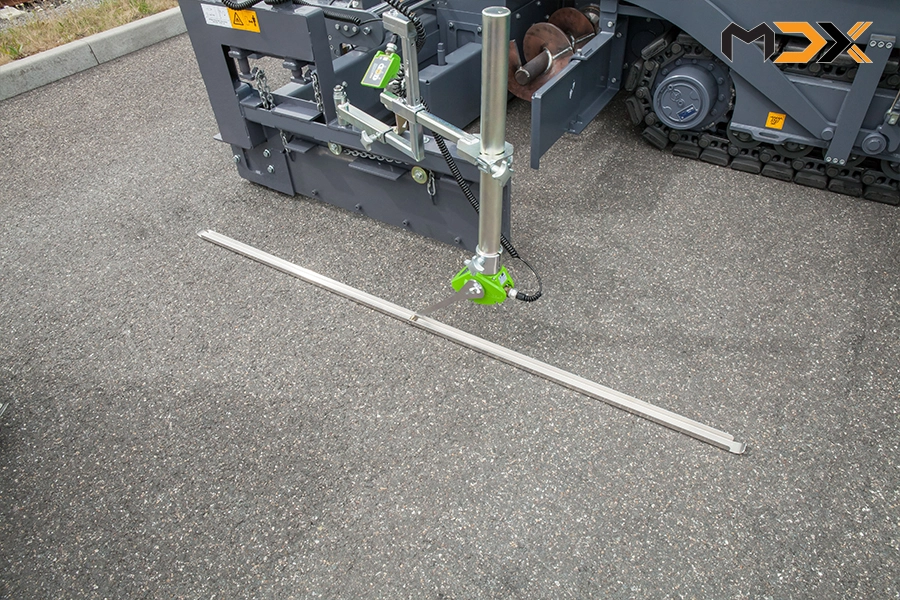

The multi-point ultrasonic sensor system consists of 3 ultrasonic sensors, a central processing unit, a solid aluminum support frame system, and a set of connecting cables. All are protected in a very eye-catching and professional iron transport case.

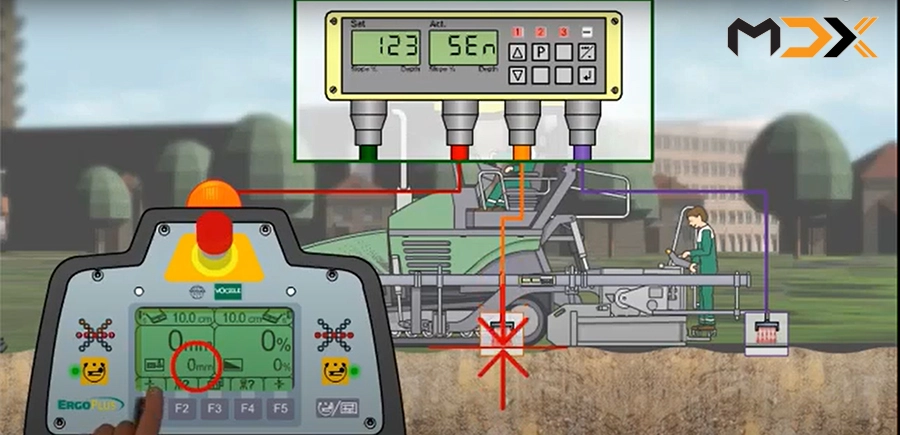

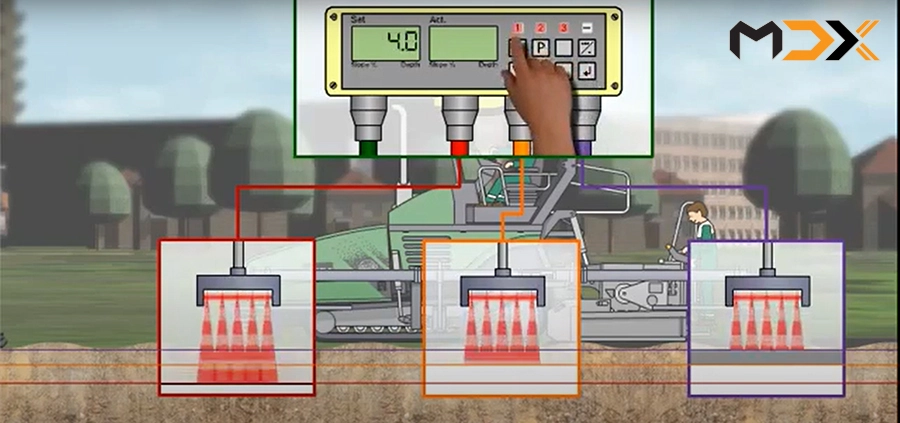

The 3 ultrasonic sensors of the multi-point ultrasonic sensor system are installed at the front, middle, and rear of the screed. The sensor at the front of the paver usually measures the height of the unpaved base course or the reference layer next to it. The sensor in the middle of the machine measures the height of the reference layer right at the screed chain.

The sensor behind the screed usually measures the height of the finished mat. Before operation, these 3 sensors will be set to a standard value of 0, meaning that: in reality, these 3 heights are different but are brought to a standard value; during operation, the ultrasonic sensors measure the variation of the reference surface and average these values.

|

|

|

| Set of 3 ultrasonic sensors | Central processing unit | Solid aluminum support frame system and wiring harness |

The Big Multiplex Ski multi-point ultrasonic sensor is the latest version that is particularly user-friendly and can be fully set up in just seven minutes. Some advantages of the Big Multiplex Ski include:

- Data acquisition for calculating flatness over a wide area.

- Very flexible installation length in the range of 5 - 13m.

- Flexible use even in curved road sections thanks to the configurable sensor rotation.

- Quick installation with couplings and clamp-type locks: can be installed by hand without any special tools. The sensors automatically recognize and display the order on the control screen of the central processing unit.

- The storage case is intelligently designed for easy inspection, loss detection, and safe transportation.

Installation is very quick thanks to the solid and intelligent couplings and clamps, the complete installation time for the multi-point ultrasonic sensor system is about 7 minutes. The sensors automatically recognize and display the order on the control screen of the central processing unit.

Description of the steps to install the multi-point ultrasonic sensor system:

Step 1: Fix the 2 mounting brackets to the screed's arms.

Step 2: Install the rotating arms.

Step 3: Fix the main brace, the center of the sensor system.

Step 4: Attach the extension braces of the sensor system.

Step 5: Fix the sensor holding bars.

Step 6: Attach the sensors in place.

Step 7: Connect the cables from the sensor to the control panels.

Sensor setup only involves confirming the sensor type during the initial setup. And this is done simply by pressing the Enter confirmation button on the central controller. Before operation, the sensors are set to a measurement value of 0 according to each position of the reference surface (all 3 sensors are set to 0 even though they are in 3 different positions, different heights) by pressing the F1 button on the control panel.

In addition, the ultrasonic sensor also allows setting the working range (normally ±10 cm) via the increase/decrease button on the central controller. This set value is clearly displayed on the screen. The set working range is the upper limit value and the lower limit value that the central controller accepts to calculate and control the screed. Values outside this working range will not be recorded, considered incorrect values and excluded from the measurement.

Contact

Contact

Contact

Contact

Contact

Contact

Contact