-

Your shopping cart is empty!

Your shopping cart is empty!

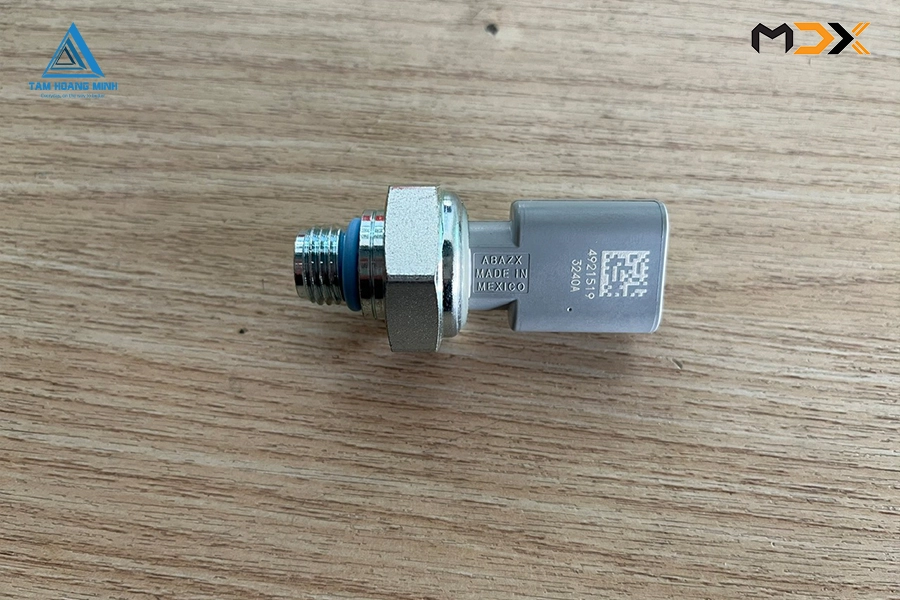

| Name | Pressure Sensor |

| Suitable for | PC200-8; S1800-3 |

| Manufacture | Cummins |

| Country of Origin | Mexico |

| Location | Vietnam |

| Contact | 0985 048 030 |

The pressure sensor is a critical component in Cummins engine systems, particularly the QSB6.7 engine, a popular choice widely used in various machinery and construction equipment. This sensor plays a vital role in monitoring oil pressure or fuel pressure within the engine, helping to control and maintain stable machine performance.

- Excavators: The QSB6.7 pressure sensor is commonly used in excavators such as the Komatsu PC200-8. With the crucial task of measuring and monitoring hydraulic oil pressure, the sensor ensures smooth system operation, preventing overload or malfunctions in the hydraulic system. This is essential for preserving component lifespan and maintaining excavator performance.

- Asphalt Pavers: Another application of the QSB6.7 pressure sensor is in asphalt pavers, specifically the Vogele S1800-3. In these machines, the pressure sensor helps control oil volume and pressure within the hydraulic system, ensuring stable operation and optimal paving efficiency. Maintaining stable pressure improves the quality of the paved surface, saves fuel, and minimizes equipment wear.

- Other Construction Machinery: Besides excavators and asphalt pavers, the QSB6.7 pressure sensor is also used in various other construction machinery such as rollers, bulldozers, and forklifts. This application helps monitor and optimize engine operation, reduce fuel consumption, and increase machine durability.

Recognizing Signs of a Faulty QSB6.7 Pressure Sensor

When the QSB6.7 pressure sensor malfunctions, the following signs may appear:

- Engine Warning Light Stays On: The control system will signal an error through the warning light on the dashboard when there is a problem with the pressure sensor.

- Reduced Engine Performance: The engine may operate erratically, experience difficulty starting, or lose power during operation.

- Sudden Increase in Fuel Consumption: If the sensor is damaged, the control system may receive incorrect information, leading to inefficient fuel consumption.

- Oil Leaks or Unstable Oil Pressure: In some cases, sensor damage can cause oil leaks or loss of pressure control within the system.

If a faulty QSB6.7 pressure sensor is not replaced or maintained in a timely manner, it can lead to serious consequences such as:

- Severe Engine Damage: Failure to control oil or fuel pressure can lead to overheating or rapid wear of internal engine components, causing significant damage and requiring costly repairs.

- Increased Risk of Workplace Accidents: Malfunctioning machinery can lead to safety hazards during operation, especially in construction or mining environments.

- Higher Maintenance and Repair Costs: Pressure sensor-related issues, if not addressed promptly, can lead to further problems, resulting in increased maintenance and repair expenses.

- Reduced Work Efficiency and Extended Downtime: Damaged machinery will affect work progress, increase downtime, and decrease productivity.

The QSB6.7 pressure sensor plays a vital role in maintaining the performance and durability of machinery. Early detection of signs of damage and timely replacement or maintenance of this sensor will help prevent serious consequences, ensuring safety and efficiency during machine operation. Investing in genuine parts and conducting regular inspections are optimal solutions to protect equipment and minimize maintenance costs.

Contact

Contact

Contact

Contact