-

Your shopping cart is empty!

State-of-the-art milling technology meets all of the requirements for cost-effective and environmentally friendly road rehabilitation. Our vision to use innovative milling technology to quickly and effectively remove road surfaces marked the beginning of the era of cold milling technology. Since then, WIRTGEN has been regarded as the global market leader in this highly complex field. Fascinated by the unimagined possibilities of the process, we are the driving force behind continuous advancement, ensuring that our innovative solutions will continue to revitalize the road network for decades to come.

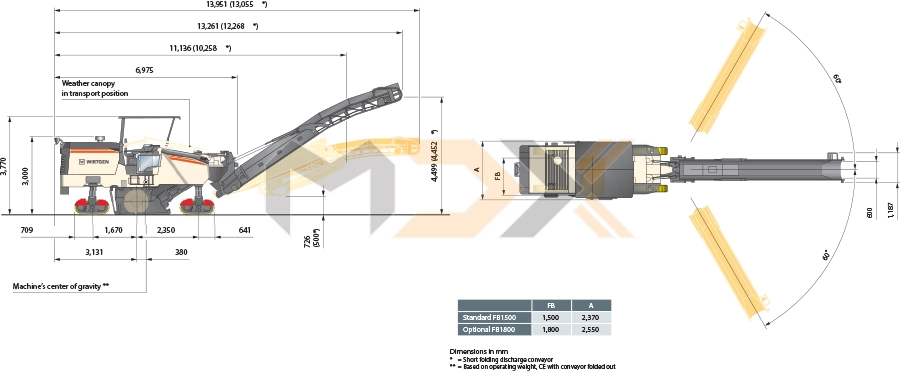

| Dimensions | ||

|

||

|

||

| Milling Drum | ||

| Standard milling width | mm | 1 500 |

| Optional milling width | mm | 1 800 |

| Milling depth*1 | mm | 0 - 330 |

| *1 = The maximum milling depth may deviate from the value indicated due to tolerances and wear. | ||

| Cutting diameter | mm | 980 |

| Engine | ||

| Engine manufacturer | CUMMINS | |

| Type | QSL 9 | |

| Cooling | Water | |

| Number of cylinders | 6 | |

| Rated power at 2 100 rpm | kW/HP/PS | 261 / 350 / 355 |

| Maximum power at 1 900 rpm | kW/HP/PS | 276 / 370 / 375 |

| Operating power at 1,600 rpm | kW/HP/PS | 250 / 335 / 340 |

| Displacement | cm3 | 8 900 |

| Fuel consumption at rated power | during a mixture of job site operations | l/h | 71 | 29 |

| Emissions standard | EU Stage 3a / US Tier 3 | |

| Electrical System | ||

| Power supply | V | 24 |

| Tank Capacities | ||

| Fuel | l | 810 |

| Hydraulic oil | l | 120 |

| Water | l | 2 250 |

| Driving Performance | ||

| Max. milling speed | m/min (km/h) | 0 - 40 (2.4) |

| Max. travel speed | m/min (km/h) | 0 - 125 (7.5) |

| Crawler Units | ||

| Track chains front / back (L x W x H) | mm | 1 330 x 260 x 550 |

| Loading of Milled Material | ||

| Belt width of primary conveyor | mm | 650 |

| Belt width of discharge conveyor | mm | 600 |

| Theoretical capacity of discharge conveyor | m³ / h | 233 |

| Basic Machine Weight | ||

| Net weight of machine without fluids | kg | 19 000 |

| Operating weight, CE*3 | kg | 20 550 |

| *3 = Machine weight, half-full tanks, vehicle tool kits, machine operator, excluding optional equipment | ||

| Maximum operating weight (full tanks, full range of equipment) | kg | 24 850 |

| Weight of Tank Contents | ||

| Water | kg | 2 250 |

| Fuel (0.83 kg / l) | kg | 670 |

| Additional Weight | ||

| Operator and tools | ||

| Operator | kg | 75 |

| 5 pick containers | kg | 125 |

| Vehicle tool kit | kg | 30 |

| Optional Milling Drum Units Instead of Standard | ||

| Milling drum housing FB1500 FCS-L | kg | 270 |

| Milling drum housing FB1500 FCS | kg | 380 |

| Milling drum housing FB1800 FCS-L | kg | 800 |

| Optional Milling Drums Instead of Standard | ||

| FB1500 FCS milling drum, HT22 LA15 with 136 picks | kg | 20 |

| FCS milling drum FB1500, HT22 LA18 with 118 picks | kg | -70 |

| FCS milling drum FB1500, HT22 LA8 with 210 picks | kg | 380 |

| FCS milling drum FB1500, HT5 LA6X2 with 512 picks | kg | 450 |

| FCS milling drum FB1500, HT22 LA25 with 102 picks | kg | -400 |

| FCS milling drum FB1800, HT22 LA18 with 135 picks | kg | 190 |

| Optional Additional Weights | ||

| Weather canopy instead of standard | kg | 450 |

| Hydraulically lowering weather canopy instead of standard | kg | -45 |

| VCS extraction system | kg | 125 |

| Leveling boom | kg | 250 |

| Additional weight at the rear | kg | 900 |

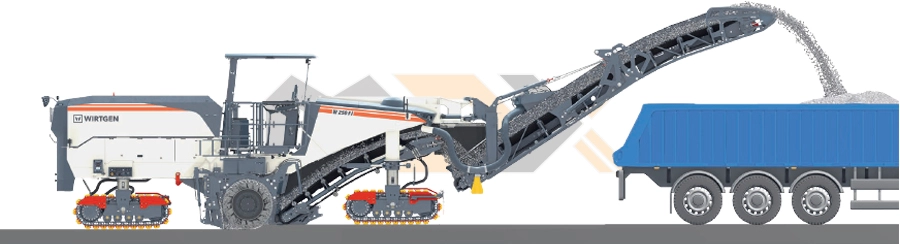

W 150 CF cold milling Wirtgen is used to remove asphalt and concrete surfaces quickly and efficiently. In doing so, they create a level foundation with the specified width and depth that is required for paving new surface layers of uniform thickness. This is important, because the condition of the milled surface has a major impact on the quality of the new surface layers, their performance characteristics, and on the cost-effective completion of further construction work. When pavements re milled in layers, the milled material can be separated and selectively recovered according to mix type.

In cold milling, a distinction is made between maintenance (minor construction measures to preserve the structural integrity of the surface), repair (major construction measures to preserve the structural integrity of the surface and improve its properties), and rehabilitation (complete restoration).

As the market leader in the field of cold milling machines, WIRTGEN has been the key driver of numerous innovations and pioneering technologies. Today WIRTGEN offers by far the most comprehensive product range in the industry.

- Milled material is generally reused as a valuable recyclable construction material.

- Both the entire thickness of the road surface and individual, thin layers can be removed.

- The cold milling method is used in a wide variety of applications worldwide and is unmatched from both an economic and environmental point of view.

Today’s technologically advanced cold milling machines can load a 30-ton truck with asphalt granulate within a few minutes. The road to this point was a long one, however WIRTGEN has always been instrumental in driving progress in this field.

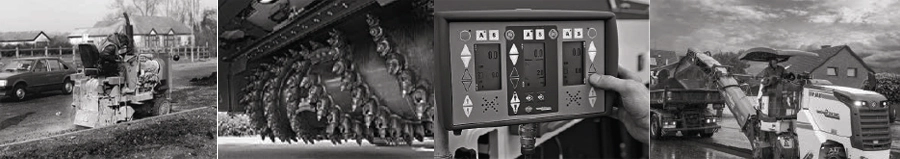

WIRTGEN built the first of a total of 100 hot milling machines for its own service fleet in 1971. The idea to use the round shank bits used in mining with carbide tips made the technological transition from hot milling to cold milling possible in 1979.

From the first building block the development of cold milling technology for road construction to the present day, WIRTGEN has reached numerous innovative milestones along the road to this technology’s success. Today, the name WIRTGEN is synonymous with high-performance cold milling technology throughout the world.

- 1971: The first prototype of a hot milling machine successfully removes damaged asphalt surfaces.

- 1979: The first cold milling machine, the 3800 C, is a rear loader with hydraulic milling drum drive.

- 1980: The 500 C, the first half-meter cold milling machine, mills to a depth of 100 mm.

- 1984: The first front loader, the 2000 VC, permanently changes job site logistics.

- 1988: The DC series with working depths up to 300 mm extends the range of applications considerably.

- 1992: The first bolted toolholder system increases cold milling machines’ operational availability

- 2001: The FCS quick-change system for milling drums increases the flexibility of the machines

- 2009: The VCS extraction system reduces dust emissions during operation.

- 2010: The new generation of large milling machines – the W 200 to W 250 sets new standards in milling performance.

- 2015: Wirtgen W 50 Ri and W 100 CFi embody a new, highly effective method of operating small milling machines.

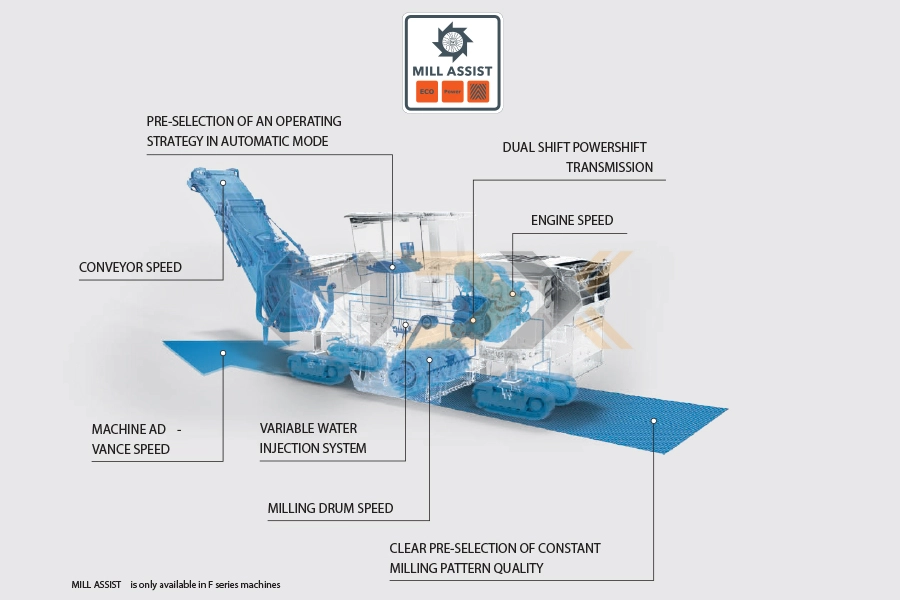

- 2019: The new F series of large milling machines, with MILL ASSIST and the Performance racker, set new standards of costeffectiveness.

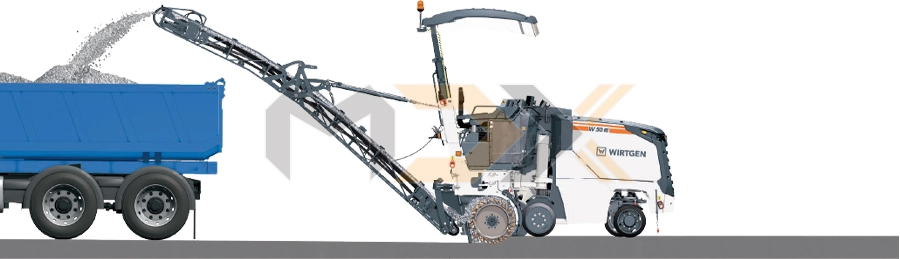

W 150 CF compact milling machine offers high mobility and flexibility. They are used for machining small surfaces and for precise milling in confined spaces and are equipped with a wheeled chassis. The milling drum is installed at the back of the machine.

- Height-adjustable discharge conveyor that can swing in both directions

- For milling flush to the edge

- Milling drums of different widths with variable tool spacings

- Operator’s platform with ergonomic multifunction armrest

- Right-side rear wheel can be pivoted in for milling flush to the edge

- Highly efficient mechanical milling drum drive

- Wheeled chassis for large front steering angle

Due to their high milling performance, large milling machines are particularly suitable for repair work on large areas. The front loaders are equipped with four hydraulically steerable and heightadjustable crawler units, with the milling drum positioned in the center beneath the machine. The proximity of the drum to the machine’s center of gravity significantly increases milling performance.

- Economical, powerful dual engine design

- Highly efficient mechanical milling drum drive

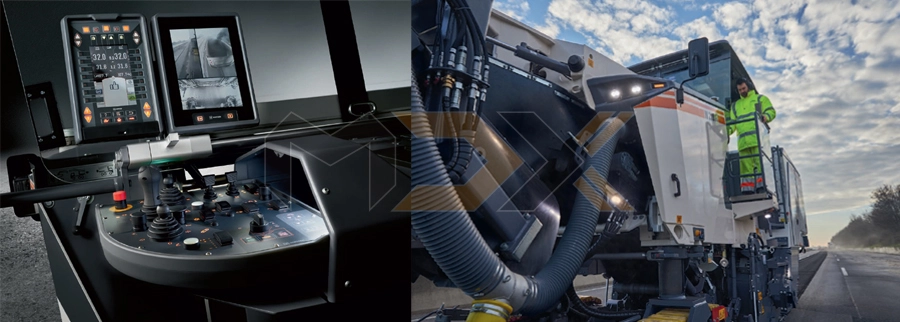

- Ergonomic operator’s platform with two workstations

- Hydraulically steerable and height-adjustable crawler units

- Hydraulically steerable and height-adjustable crawler units

- Primary conveyor for receiving the milled material

- Continuously adjustable conveyor speed

- Height-adjustable discharge conveyor that can swing in both directions

- Vacuum cutting system for the extraction of fine material particles

- Material transfer

In order to efficiently remove pavement with precision, it is essential that the milling drum, pick holder, and round shaft pick work together perfectly. WIRTGEN is the market leader in cutting technology and offers customers high-performance cutting systems whose components are designed to be fully compatible. In addition, WIRTGEN continuously makes advancements to these cutting technology components, incorporating its practical experience and feedback from customers into the process.

The heavy-duty picks offer maximum wear resistance. This increases milling performance and extends the intervals between tool changes.

The rugged HT22 toolholder system minimizes downtimes and increases the service life of the entire milling drum.

The HT22 PLUS toolholder upper part features innovative centering marks (Fig. 3) on the tool contact surface. In combination with the X² generation of round shaft picks, this reduces toolholder wear by up to 25% and also optimizes the rotation behavior of the picks. The upper part offers considerable benefits such as higher milled surface quality and longer intervals between changes.

WIRTGEN milling drum units are the perfect combination of expertise acquired over more than 50 years and groundbreaking technologies. The unique slot profile with innovative centering function on the wear plate increases the service life of the generation X2 picks by up to 25%. Detailed view of the generation X2 HT22 Plus round shaft pick.

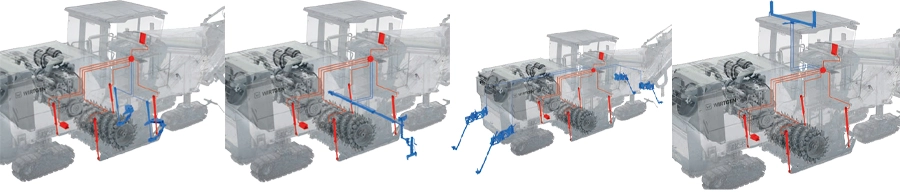

When milling, it’s important to remove the layers of asphalt at the specified depth. WIRTGEN’s intuitive LEVEL PRO/ LEVEL PRO PLUS /LEVEL PRO ACTIVE leveling technology can be relied on to precisely maintain the specified milling depth. The high-tech leveling system developed in-house at WIRTGEN with software specially programmed for cold milling machines is fully integrated into the control system of the entire machine. LEVEL PRO/LEVEL PRO PLUS / LEVEL PRO ACTIVE constantly compares the current milling depth with the preset target value.

If the system detects deviations, they are dynamically and proportionally corrected. The actual milling depth is determined via optical or mechanical sensors that continuously scan a reference surface.

The WIRTGEN leveling system can not only be operated with a wide variety of sensors, but can also be extended as required for example with the multiplex system, laser leveling, or thanks to a preinstalled interface, with 3D leveling.

- WIRTGEN’s leveling technology adjusts height, depth, and pitch for extremely accurate results and reduces the operator’s workload.

- LEVEL PRO/ LEVEL PRO PLUS/ LEVEL PRO ACTIVE stands for perfect leveling quality at high working speeds.

- Scanning in front of the milling drum.

- Telescoping leveling boom on the right or left.

- Multiplex system with up to four ultrasonic sensors.

- 3D leveling/ laser leveling.

State-of-the-art cold milling machines are efficient construction machines whose key success factor is their high milling performance. Intelligent, computer-assisted automatic functions assist the operator so that they need to intervene in the milling process as little as possible. With WIRTGEN high-performance cold milling machines, for example, the operator is supported by the innovative proprietary MILL ASSIST machine control system.

In automatic mode, MILL ASSIST always selects the operating strategy with the best balance between performance and costs. In doing so, the process optimization automatically adjusts the speed of the diesel engine and milling drum, the travel drive, the water system, and the machine’s advance speed. This significantly reduces the operator’s workload while improving machine performance and considerably reducing diesel consumption, CO2 emissions, and noise.

- Intelligent computer control systems support the machine operator during their daily operations.

- The milling machine’s intelligently designed visibility concept makes the operator’s work much easier and results in precise milling results.

- The innovative MILL ASSIST machine control system helps the machine operator optimize the results of the milling process.

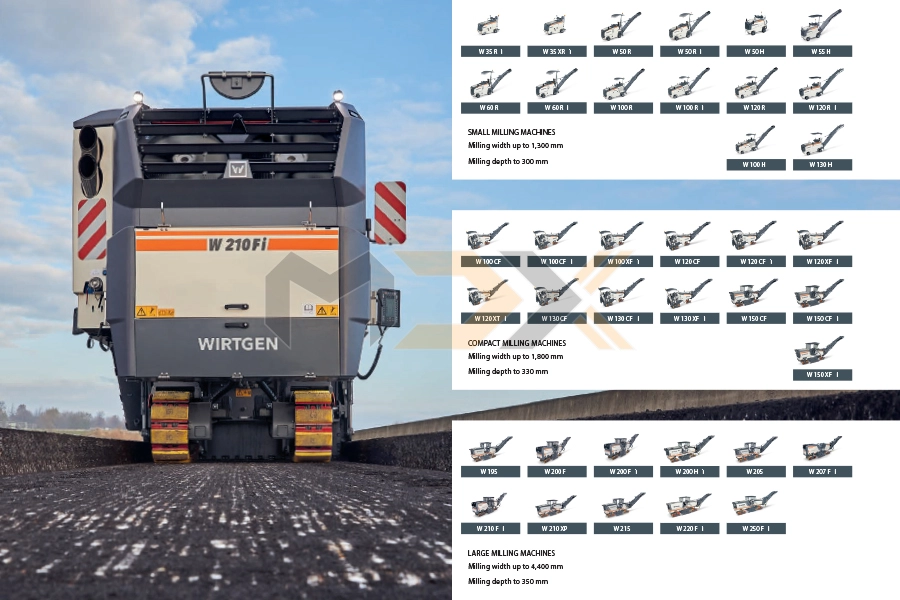

WIRTGEN offers by far the widest range of cold milling machines worldwide. The standard range already covers the entire milling width spectrum from 14 mm to 4.4 m. The selection of machines extends from the extremely compact W 35 Ri cold milling machine – which is also suitable for indoor applications to the W 250 Fi, which is capable of completing major projects on highway or airport job sites in record time.

Our delivery range leaves nothing to be desired. It offers a customized, state-of-the-art solution for every customer-specific application. From additional milling drums to the optional VCS dust extraction system to the hydraulically adjustable and rotating operator’s cabin (OCS) to name just a few options customers can generally select from a large number of equipment options for their cold milling machines to ensure that they always achieve maximum performance, even under complex job site conditions.

Small Milling Machines

WIRTGEN’s small milling machines stand out particularly for their outstanding versatility and flexibility. Thanks to their maneuverability, they are the ideal solution for milling jobs where space is at a premium. Their compact dimensions also make it easier to transport them.

The machines’ minimal milling radius is ideal for milling around road installations and obstacles as well as around tight curves. In addition, special milling drums and ancillary equipment make it easy to mill rumble strips, slots, and tie-ins.

Small milling machines are also the best choice for the rehabilitation of industrial spaces and production hall floors due to their small size. The same applies to patching specific sections of road or adding and removing road surface markings.

Compact Milling Machines

W 150 CF compact milling machines from WIRTGEN combine the benefits of small and large milling machines and therefore offer tremendous flexibility. The machines, which are operated as front loaders, are particularly maneuverable on the one hand, but also offer a high level of performance on the other.

As a result, the compact class is suitable for milling jobs in tight spaces, for example, but also for removing entire road surfaces. Original WIRTGEN fine milling drums can be used to produce specific surface structures.

Compact milling machines can also be used for spot road repairs and the removal of road pavements in layers, as well as for smoothing out irregularities in the surface layer.

Large Milling Machines

WIRTGEN’s most powerful class of milling machines is particularly suitable for the rehabilitation of large areas. Their impressive milling performance means that large milling machines can complete construction projects much faster, thereby minimizing traffic disruptions.

Front loading ensures that the milled material is optimally loaded, and keeps the milling process flowing by continuously filling the trucks on the fly. In addition, this allows the trucks to move in and out smoothly in the direction of traffic.

Large milling machines countless applications include he removal of road pavements in layers or the complete removal of road surfaces at milling depths of up to 35 cm.

Special milling drums can also be used to produce specific surface structures (fine milling) and improve grip. Large milling machines are also the first choice for smoothing out irregularities in the surface layer.

ONE-OF-A-KIND PRODUCTS

- Thanks to our decades of experience in the cold milling business, our machines are the most innovative on the market.

- W 150 CF cold milling machine from WIRTGEN are renowned for their consistently high performance, excellent quality, and maximum reliability.

A CLOSE RELATIONSHIP WITH CUSTOMERS

- Your opinion is important to us, which is why our sales team with its excellent knowledge of our products engages in a dialog with every customer and always puts your needs first.

- With its comprehensive technical expertise, our service team ensures that your W 150 CF cold milling machine will have a long service life - we remain your reliable partner long after the sale.

As the global market leader in road construction, we have a responsibility to the environment which we take extremely seriously. For example, the selectively milled material is completely reused as a valuable recyclable construction material. In addition, we constantly strive to reduce machine emissions through groundbreaking advancements and environmentally friendly engines.

As the global market leader, here at WIRTGEN we strive to meet our own high standards each and every day. This is why we are particularly proud of the fact that all of our machines are fully developed and manufactured in-house. From the idea to the design and production through to sales and service, our products are supported exclusively by extremely well-trained WIRTGEN employees.

In the process, our customers’ opinions and interests play a particularly valuable role. This is because in addition to providing excellent after-sales service after the purchase of a machine, receiving feedback from customers which we incorporate into the development of new products is extremely important to us.

STANDARD EQUIPMENTS FOR W 150 CF COLD MILLING MACHINE

| Basic Machine |

| Basic machine with engine |

| Machine chassis with wasp waist on the right side (zero edge) |

| Electrohydraulically opening engine cowling |

| Radiator with temperature-dependent fan speed |

| Additional control switch for scraper blade, bottom right |

| Elastically mounted engine station with low vibration and low noise |

| Three milling drum rotation speeds with electric on / off function 106 r.p.m. - 96 r.p.m. - 86 r.p.m |

| Air compressor system |

| Milling Drum Assembly |

| The right side of the milling drum housing can easily be folded down for maintenance or milling drum change |

| Hydraulic material depressor with conveyor lifting function |

| Hydraulically opening scraper plate with convenience locking |

| Exchangeable wearing segments on the side plate |

| Loading of the Milled Material |

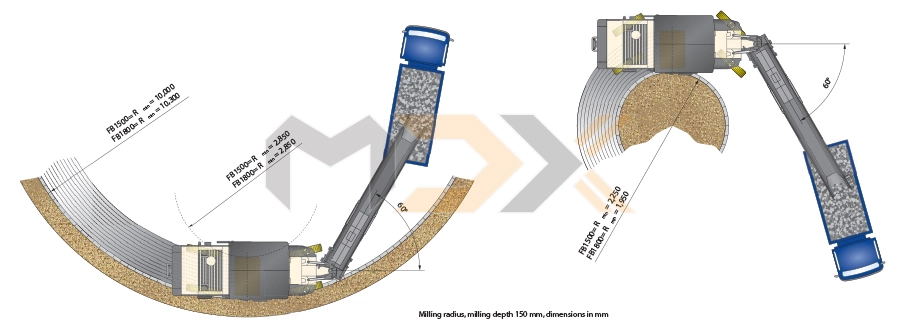

| Discharge conveyor slewing angle left 60 degrees - right 60 degrees |

| Hydraulically foldable discharge conveyor with two swing speeds, including adjustable conveyor speed for precise loading |

| Machine Control and Leveling System |

| LEVEL PRO PLUS leveling system right and left |

| RAPID SLOPE cross-slope sensor for LEVEL PRO ACTIVE leveling system |

| Load-dependent advance control |

| 4-track drive with manually activated, electronic anti-slip control |

| 4 selectable steering modes |

| Automatic engine speed control |

| Operator´s Platform |

| Convenient control panel with practical switches |

| Multifunctional armrest including color operating display for one-handed operation of most machine functions |

| Digital multi-function display for all important operating conditions |

| Scraper height indicator on control panel |

| Operating panel nighttime lighting |

| Robust anti-vandalism protection for the controls |

| Adjustable steering wheel position |

| Optimally positionable operator’s seat |

| Footstep right and left with conveniently folding ladder |

| Two mirrors front, one mirror middle and one mirror in rear area of the machine |

| Track Unit and Height Adjustment |

| Jog mode for height adjustment |

| Fourfold full-floating axle for high machine stability |

| PTS – automatic alignment of the machine parallel to the pavement surface |

| ISC – intelligent track speed control including hydraulic four-track drive |

| Reversing with the milling drum rotating. Simple and fast maneuvering |

| Equipped with extremely wear-resistant 2-piece polyurethane track pads |

| Miscellaneous |

| Automatic water management |

| Large tool package |

| Generously sized water and diesel tanks |

| Total of 3 EMERGENCY STOP switches at sensible positions on the machine |

| “Welcome” and “Go home” lights feature including LED lighting in the area of the operator’s platform and access |

| Pre-fitting for installing the WITOS FleetView control unit |

| European type certification, EuroTest mark and CE conformity |

STANDARD EQUIPMENT, CAN BE REPLACED WITH OPTIONAL EQUIPMENT IF DESIRED

| Milling Drum Assembly |

| Milling drum housing FB1500 |

| Milling Drums |

| Milling drum FB1500 HT22 LA15 with 136 picks |

| Loading of the Milled Material |

| Machine with hydraulic standard coupling for the discharge conveyor |

| Discharge conveyor, 8 150 mm long, 600 mm wide, with hydraulic folding device |

| Operator´s Platform |

| Standard operator’s seat |

| Miscellaneous |

| Standard painting in RAL 9001 (cream) |

| WITOS FleetView – professional telematics solution for machine operation and service optimization |

| Halogen / LED lighting system including rotating beacon |

| Electrohydraulic unit |

OPTION EQUIPMENT FOR W 150 CF COLD MILLING MACHINE

| Milling Drum Unit |

| Milling drum housing FB1500 FCS-L |

| Milling drum housing FB1500 FCS |

| Milling drum housing FB1800 FCS-L |

| Milling drum housing FB1200 FCS |

| Overload sensor on the scraper |

| Active floating position for the side plates, left and right |

| Milling drum rotation device |

| Milling Drums |

| FCS milling drum FB1500 HT22 LA15 with 136 picks |

| FCS milling drum FB1500 HT22 LA18 with 118 picks |

| FCS milling drum FB1800 HT22 LA18 with 135 picks |

| FCS milling drum FB1200 HT22 LA15 with 109 picks |

| FCS milling drum FB1200 HT22 LA8 with 174 picks |

| FCS milling drum FB1200 HT5 LA6X2 with 410 picks |

| FCS milling drum FB1200 HT22 LA25 with 87 picks |

| FCS milling drum FB1500 HT22 LA8 with 210 picks |

| FCS milling drum FB1500 HT5 LA6X2 with 512 picks |

| FCS milling drum FB1500 HT22 LA25 with 102 picks |

| FCS milling drum FB1800 HT22 LA8 with 248 picks |

| FCS milling drum FB1800 HT5 LA6X2 with 608 picks |

| FCS milling drum FB1800 HT22 LA25 with 114 picks |

| FCS milling unit FB600 HT22 LA12 with 79 picks |

| FCS milling unit FB900 HT22 LA15 with 102 picks |

| FCS milling unit FB1200 HT22 LA15 with 109 picks |

| Loading of the Milled Material |

| Machine with hydraulic quick-change coupling for the discharge conveyor |

| Shortened discharge conveyor, 7,250 mm long, 600 mm wide, with hydraulic folding device |

| VCS extraction system |

| Additional storage compartment on the discharge conveyor |

| Machine Control and Leveling System |

| Additional control unit for operating the machine from the ground, left |

| SONIC SKI sensor for LEVEL PRO PLUS leveling system |

| Scanning in front of the milling drum unit |

| Additional operating display LEVEL PRO PLUS |

| Multiplex pre-fitting comprising 4 sensor sockets and holder |

| 3-way multiplex system, right, including 2 ultrasonic sensors |

| 3-way multiplex system, right and left, including 4 ultrasonic sensors |

| Level control 3D leveling pre-equipment |

| Basic equipment laser leveling without laser transmitter |

| Milling depth measurement and display in the LEVEL PRO PLUS display |

| Job data acquisition in the control display |

| Operator´s Platform |

| Comfort operator’s seat incl. seat heating |

| Weather canopy with electro-hydraulic fold-down feature |

| Operator’s platform heater |

| Track Unit and Height Adjustment |

| Increased traveling speed (up to 7.5 km / h) |

| Precision steering by pushbuttons |

| Miscellaneous |

| Standard film coating in RAL 9001 (cream) |

| Film coating according to the customer’s wishes |

| Model without WITOS FleetView |

| High-power lighting system LED including rotating beacon |

| Extended electro-hydraulic unit |

| Additional weight 900 kg |

| Milling drum assembly trolley to FB1500 |

| Electrical fuel filter preheating |

| Signal lights for visual “stop” and “go” instructions for the truck driver |

| Pre-equipped for LED lighting balloons |

| Hydraulic filling pump for water tank |

| Powerful high-pressure water cleaner, 150 bar, 15 l / min |

| Pneumatic hammer with pick extractor / inserter |

| Hydraulically driven pick extractor drift |

| Additional folding seat for pick change with storage compartment |

| Diesel tank filling pump with 5.00 m suction hose |

| Monitor system with 2 cameras and screen |

| Monitor system with 5 cameras and 2 screens |

| LED lighting balloon, 24 volt |

| Licence plate holder with LED lighting |

| Large storage compartment at the rear of the machine |

Tags: cold milling machine, cold milling wirtgen, W 50 R, w 60 r, w 100 r, w 120 r, W 100 CF, W 120 CF, W 130 CF, W 150 CF