-

Your shopping cart is empty!

You build the finest roads so we can all move forward faster. And to ensure that you can progress faster, we build the best machines. As a member of the leading international FAYAT group, we supply machines for all areas of road construction – from soil compactors to cold planers and recyclers, from asphalt rollers to road pavers. For over 60 years, the history of our company has been synonymous with the history of road construction.

With our accumulated know-how, we are an innovation driver that sets the pace for an entire industry. BOMAG has developed a huge number of technologies, from systems for measuring and controlling compaction, such as ECONOMIZER and ASPHALT MANAGER, to technologies for reducing operating costs, such as ECOMODE and the most effective screed heating in the market: MAGMALIFE. We offer solutions for a wide range of applications.

Our global network of experts and partners in over 120 countries is there to support you, from the configuration of the machines to providing solutions for the most challenging of tasks.

We owe our innovative strength to our more than 2,500 employees worldwide, their commitment and their unique wealth of experience. A source of know-how which has propelled us to worldwide market leadership in this sector. The reason for this is our unconditional commitment to quality: in product development and production, in the qualification of our employees, and in a service that guarantees optimal on-site support

|

||

|

||

|

||

|

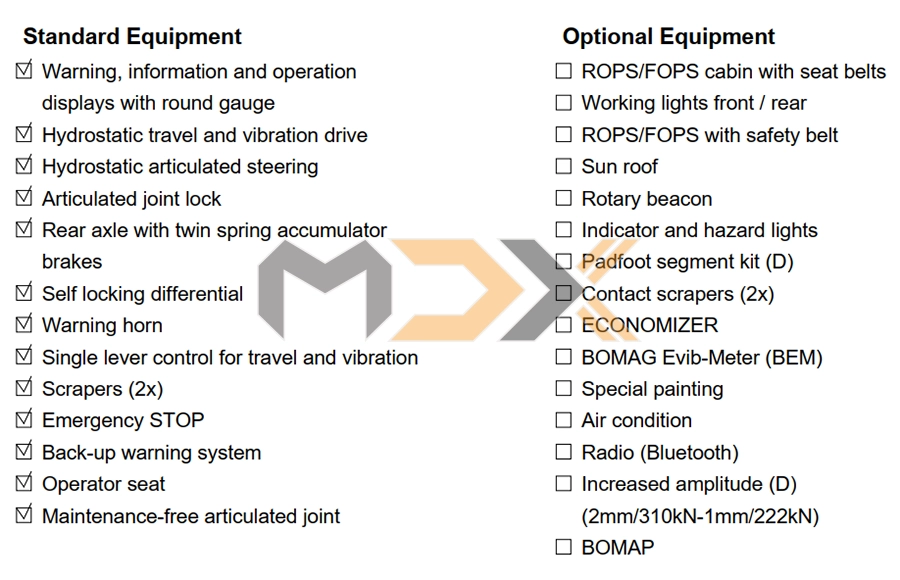

Note: standard or optional equipment depends on the standard of each country. Please contact us for the answer.

|

BOMAG measuring technology gives control of compaction during rolling operations. Surface area coverage with precision. How can efficiency and quality be improved during compaction on earthworks and asphalt? By using smart systems which show and document the compaction status

- No unnecessary passes

- Fewer inspection controls required

- Uniform compaction

- No overcompaction

- Complete documentation

- Makes compaction work easier

BOMAG offers customised measuring systems for any machine class – from vibratory plates to the heaviest single drum roller. No other manufacturer compares with BOMAG’s decades of application expertise as market leader.

No two construction sites are the same. Measuring technology applications are in demand for earthworks and asphalt construction to suit different specifications. BOMAG therefore offers a three-stage modular system.

The compaction is displayed to the driver so that the machine is optimised and the number of passes can be controlled.

Based on the measured compaction, the machine adjusts its own control settings using the BOMAG-developed smart compaction systems.*

*Please refer to the ASPHALT MANAGER and VARIOCONTROL brochures for more details

The entire process is documented. The results can be used for self-monitoring or made available to the client.

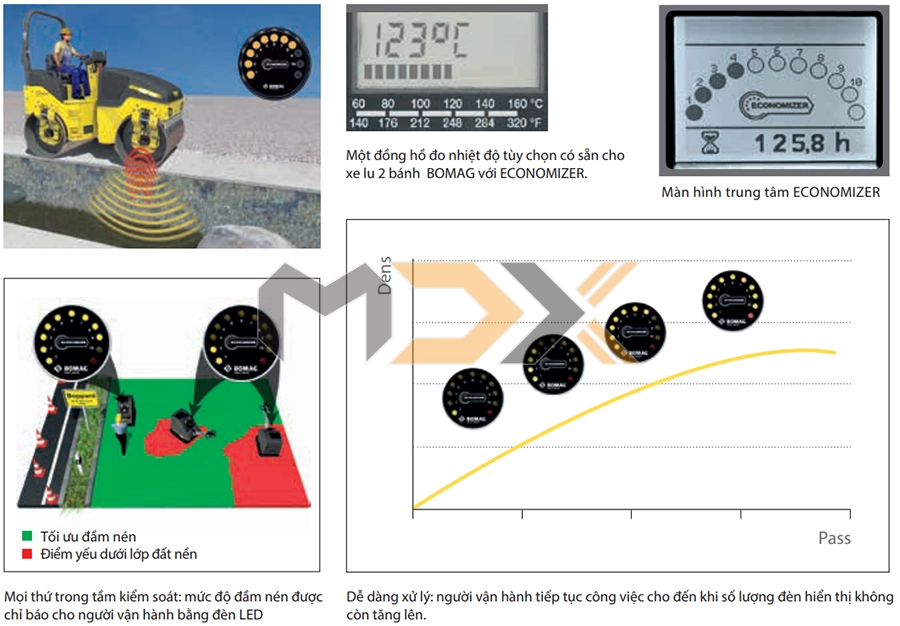

BOMAG makes everything going on under the machine measurable and visible. The ECONOMIZER shows the operator the degree of compaction on a display helping to achieve the best compaction results. Operation is very simple, because no set-up or calibration is required.

The ECONOMIZER automatically determines the compaction progress. A light strip indicates the end of compaction to the driver to avoid overcompaction. A warning lamp also indicates when there is a risk of overcompaction developing.

Efficient compaction is not just a question of size. ECONOMIZER is available for:

- BPR vibratory plates

- BMP trench compactor

- BW 90-138 light tandem roller

- BW 141-206 heavy tandem roller

- Single Drum Rollers -5 and -40

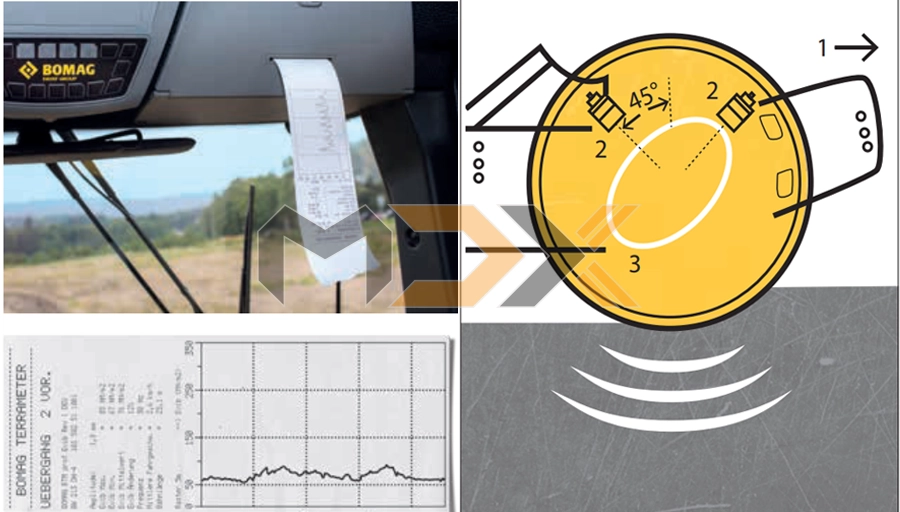

In earthworks, the stiffness of the material, measured with a pressure plate, is often used as a benchmark. However, load plates only measure certain points and are costly. TERRAMETER has the technology to do far more. This measuring system allows BOMAG single drum rollers to become rolling pressure plates: surface area covering, in real time.

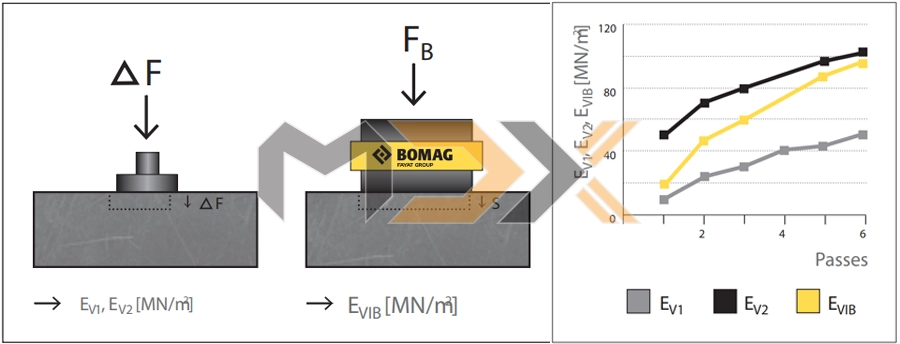

TERRAMETER measures the level of stiffness EVIB in MN/m². EVIB correlates directly to the EV1/EV2 values from the plate load test. This means the operator not only sees the trend, but also specific, absolute measured value. The operator can then directly work towards the required stiffness level specified by the client.

The standard DIN set values for EV2 of 45, 80, 100 and 120 MN/m² are shown on the display as a step change. This allows the target achieved to be quickly displayed. Additionally, the operator is notified by a red LED that compaction has not increased between two passes.

For an initial on site evaluation, the printer is a logical optional addition to the TERRAMETER. It documents the EVIB track as far as 150 metres, as well as minimum, maximum and average

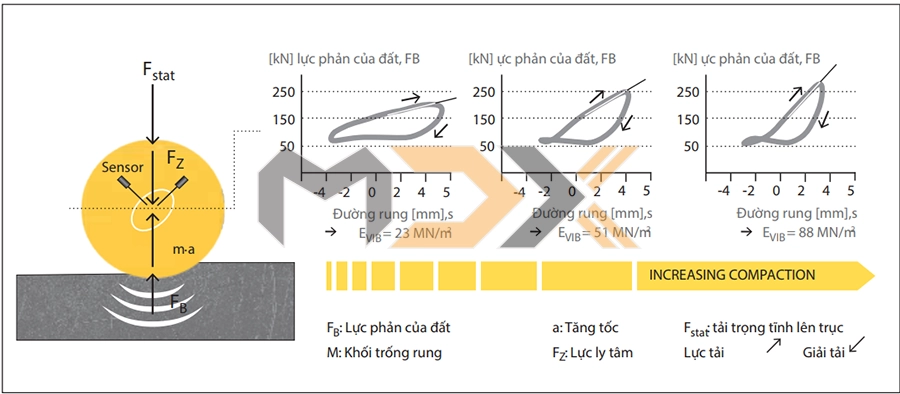

HOW EXACTLY IS THE EVIB -VALUE CREATED?

EVIB uses the interaction of the acceleration of the vibrating drum and the stiffness of the soil. In general, the soil stiffness will increase as compaction increases. The principle corresponds with a dynamic load plate.

If the soil becomes stiffer, the drum acceleration will also increase. The measuring sensors record this acceleration and from this determine the effective contact force between the soil and drum and, at the same time, the vibration path of the drum. If the contact force is then laid on top of the vibration path of the drum, this results in a loading and unloading curve for every revolution of the exciter. The EVIB value corresponds with the increase in load curve, as this correlates with the stiffness of the soil.

Only BOMAG uses two measuring sensors on the drum to optimise measuring accuracy. The measuring frequency is also unequalled: the EVIB value is continuously measured with a measuring density of just 10 cm. This ensures that every weak spot is detected.

TERRAMETER is available for all single drum rollers -5 and as standard in single drum rollers with VARIOCONTROL.

The name tells it all: BCM stands for BOMAG Compaction Management. It is used to manage and fully document compaction over an entire construction site

A tablet PC suited to construction sites and a GPS receiver form the basis for creating complete compaction maps. This means the operator receives direct feedback about how to optimise the rolling pattern. All data are documented for subsequent analysis.

CHOOSE FROM THREE DIFFERENT VERSIONS:

- BCM start

- BCM 05

- BCM net

The systems have a modular set-up. Hardware is compatible and an upgrade is possible at any time. The components can be interchanged between machines.

BCM start is the plug-and-play application for roller passes. The driver just has to press the start button and watch as the roller follows its tracks. No preparation is needed. Colour is used to indicate how many passes have already been made. On asphalt, the colour additionally indicates the surface temperature. Colour assignment can be changed at any time. When the required number of passes has been reached, the button turns green. This makes the operator’s job so much easier: He no longer has to concentrate on the rolling pattern, just on “making everything green”. This means more attention is paid to handling the roller and on safety within the driver’s surroundings, and in obtaining a uniform result

BCM start works on any roller, regardless of make or technology – in other words, also with static rollers. The only thing needed is a power supply. In addition to displaying the rolling pattern, BCM start also provides documentation. Both passes and temperatures are saved and can be read out as a PDF file any time from the tablet PC via USB. This will also be favoured by the client

BCM 05 makes the roller a QA tool, as the BCM 05 tablet PC communicates with the BOMAG roller, and also processes EVIB and ECONOMIZER values. In addition to the “pass” and “temperature” parameters created by BCM start, a true map of compaction values is also created in BCM 05.

Another component of BCM 05 is the software tool BCM office. This allows convenient creation and management of projects. Preparation and analysis take place in the site office; the roller driver simply has to start up the tablet PC. Communication between the tablet and office is by USB stick.

The import of points and lines from other GIS applications allows real mapping of the construction site, making orientation easier. On site, points can be created to enable measuring locations to be assigned to them.

There are comprehensive aids available in BCM office for statistical analysis and correlation of the measured results. All results are displayed clearly as required using the print manager. The data is safe from manipulation. All parameters can be analysed at any time. Every roller track and every position is saved. Variations and compliance with specified values are visible. All this with a high resolution of up to 10 cm.

This provides efficient self-monitoring and helps keep clients satisfied! The BCM 05 can demonstrate that the contractor has done everything to spec. The BCM 05 is the only system on the market that can work without a GPS receiver. This can be really useful, e.g. when working in tunnels or inside structures. Only the tracks to be rolled are defined.

In asphalt construction, several rollers often work together simultaneously. The distance to the paver has to be correct, and the temperature too. And then the water supply has to be refilled. How do roller operators monitor everything? With BCM net!

BCM net links up all rollers working in the compaction process. Each driver has the current overall picture of passes made and temperature and can react fast.

BCM net establishes a direct WLAN network. The individual rollers are able to communicate directly with each other. The advantage: BCM net works independently of mobile networks and incurs no extra running costs. In addition, only this technology allows real time mapping of the site - without diversions via servers or mobile networks. And of all applications asphalt compaction is where time is the key factor.

Preparation and analysis are carried out conveniently with the familiar BCM 05 office software. On site, a roller is defined as the “server” which centrally collects and distributes the group’s data. Even the paver can be integrated: the roller operators then see on their displays the mat track which the paver has laid and the temperature, all of which assists decision making.

BCM and StarFire have all global standard coordinate systems pre-installed as standard. The local position transformation required is simply selected and away it goes. BCM also has unassigned interfaces for NMEA strings which enable communication with all standard receivers. This allows an existing on site infrastructure to be used to best effect.

The BOMAG BCM systems are provided from one source ready to go: tablet, software, installation and GPS receiver can be mounted ex works, or installed any time as a retrofit kit on site. The advantage for you: always the same specialist contact. The BOMAG StarFire receiver combines the advantages of great accuracy with easy installation. Both GPS and GLONASS are used. The lane-to-lane accuracy is a minimum of 22 cm – an ideal value for the working width of rollers. The SF1 correction signal used for this is available free of charge. The SF2 signal, which can be supplied subject to charge, can increase accuracy to 5 cm. Neither of these two signals requires a costly local base station (RTK). All components are integrated in the compact StarFire receiver. This allows the StarFire receiver to be installed under machines quickly and conveniently, or stored to prevent theft. There is no need for specialist staff to commission the system.

Whether for BOMAG rollers or machines from other manufacturers: BCM stands for absolute precision on construction sites. The reason is the use of state-of-the-art networking technologies and GPS navigation.

Tags: bomag compactor for sale, bomag compactor parts, bomag compactor plate, bomag compactor dealer, bomag compactor weight, bomag compactor specs, bomag compactor oil, bomag compactor manual, how to start a bomag compactor, used bomag compactor, bomag roller compactor, bomag roller for sale, bomag roller parts, 120 bomag roller, 80 bomag roller, double drum bomag roller, bomag rollers, bomag 120 roller, bomag 120 roller for sale, bomag trench roller, bomag 80 roller for sale, bomag 80 roller, bomag 55 roller for sale, bomag 120 roller weight, bomag double drum roller