To achieve the best paving quality you need to rely on a high-performance screed, smooth material flow and an efficient, powerful drive. The paving quality is measured in compaction, evenness and profile - the Dynapac SD paver range will help you to achieve your paving goals!

Our intelligent control system PaveManager 2.0 combined with the new 7” display provides you with excellent monitoring of the complete paving process and ensures an optimal material flow. RemoteControl 2.0 in tablet design is convincing with user-friendly operator concept. PaveManager 2.0 offers advanced features such as a real time paving parameter overview, paving parameter memory function and automatic crown and slope settings. Combined with additional sensors, PaveManager 2.0 can also display real-time layer thickness and working width data.

HIGHLIGHTS

SMOOTH MATERIAL FLOW

SAFE IMPACT SYSTEM™

Dynapac tracked paver SD2500CS offer the safe impact system™ - a hydraulic anti-shock push roller that avoids the typical marks on the surface due to truck docking. The system also extends the docking length and gives you flexibility when working with different truck models.

ROCK DEFLECTOR

Our electrical rock deflector offers the extra comfort. It is moveable via Remote Control 2.0 and operator panel.

TRACTION

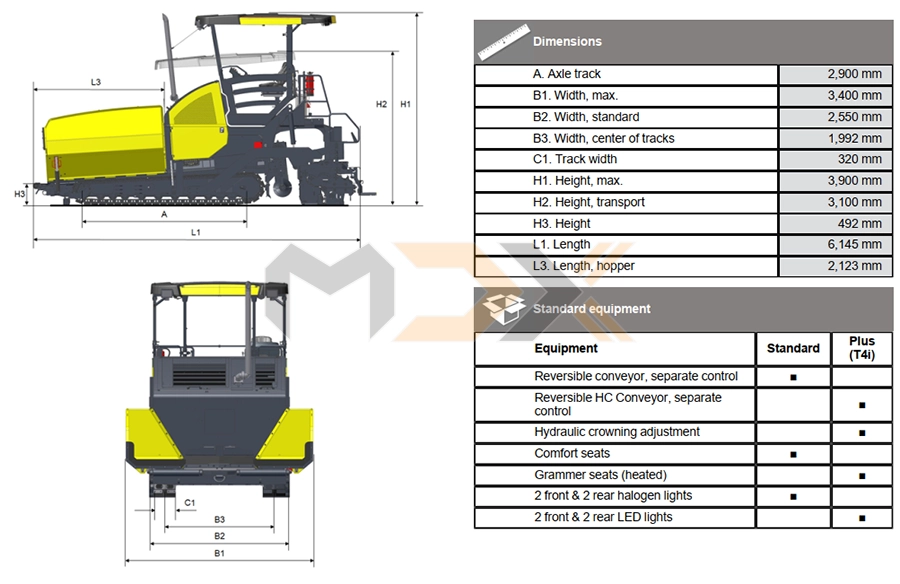

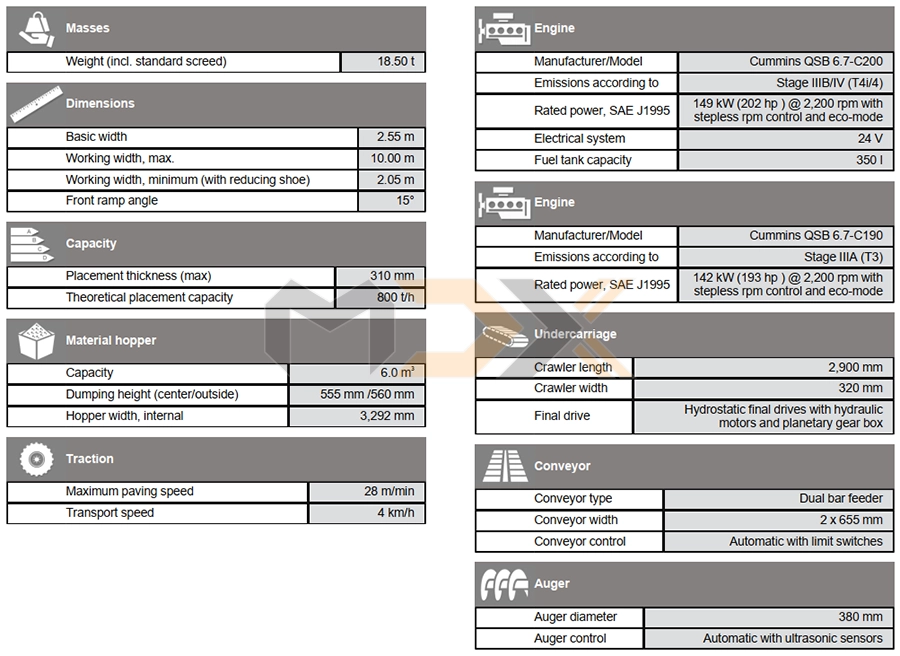

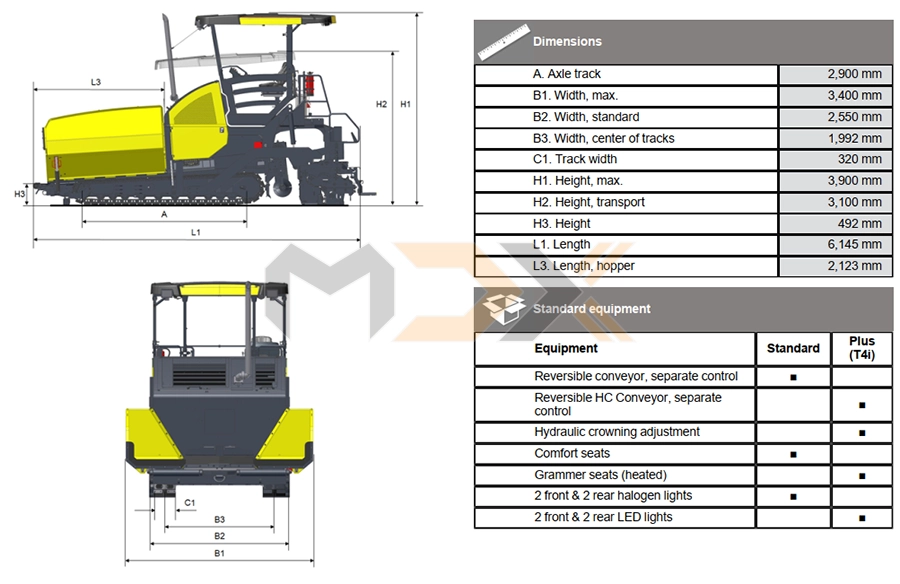

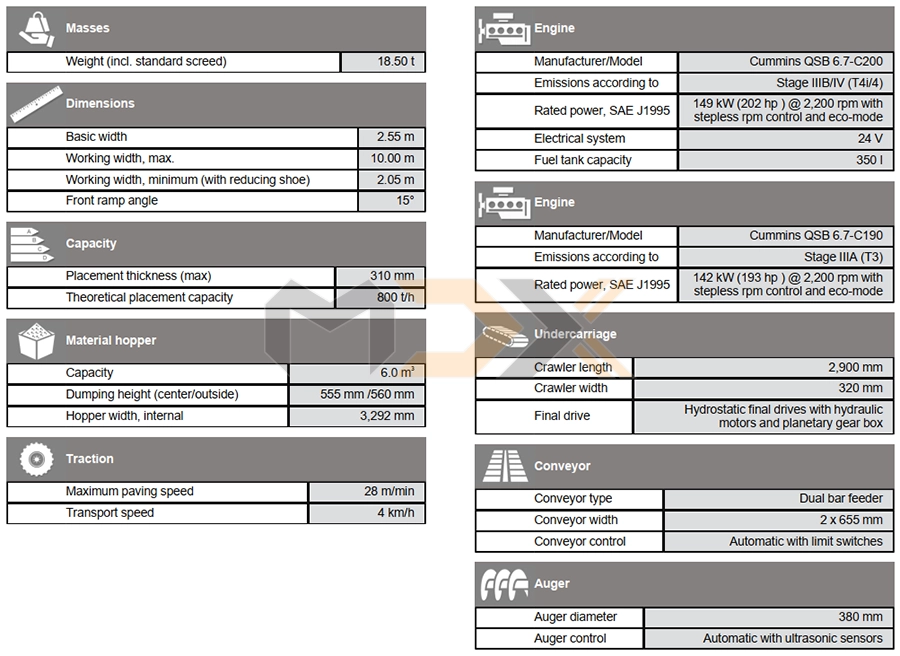

Our Alpha-Track™ system is longer and wider to give you a smooth drive behavior and a perfect grip. The rubber track pads are 320mm wide which creates great ground contact. A high number of rollers inside the tracks improves the manoeuverability on curves. The tracks are also very low to give an optimal dumping height. These track pads are especially designed for paving application and have higher rubber thickness for longer life and lower cost.

MATERIAL FLOW

Dynapac SD2500CS has designed the hopper with chamfered hopper edges to avoid cold asphalt sticking in the corners. A hydraulic front hopper flap reduces material spillage on the push rollers and on the road. It also helps to completely empty the hopper and reduces the amount of hand shovelling required. A very low dumping height makes collision with trucks almost impossible. The generous hopper leads to the widest conveyor tunnel on the market. The tunnel is shaped to create the best flow and to avoid any segregation of asphalt material.

The twin conveyor system, 2 x 655 mm wide, with reversible drive, offers smooth material flow without segregation. We have a standard conveyor as well as a high capacity conveyor with double the number of conveyor bars for improved material flow. The auger compartment is fully visible from the operator’s position. The auger and auger tunnel are easily extended to fit wider working widths.

POWERFUL AUGER SYSTEM

The Dynapac auger drive system is an improved centrally driven system with a slim gearbox (15cm) and small outer bearings that allow homogeneity of mixture, despite the high material throughput of up to 1100 tons per hour.

The left and right auger drives have independent and reversible controls. This strong auger system has a torque to handle auger diameters from 380 mm up to 500 mm. In order to achieve optimized material flow for different paving thicknesses you can adjust the auger height hydraulically up to 250mm while paving.

HIGH PERFORMANCE SCREEDS

4-TUBE PRINCIPLE

Dynapac screeds are the most appreciated screed on the market, worldwide! The screed is extremely stable due to our well-proven four-guiding tube principle which offers unmatched screed stability. Our screeds are easy to assemble while they don’t need any supporting rods, even at large working widths. This allows you to fully focus on the paving process and save money on set-up times.

ELECTRIC OR GAS - YOUR CHOICE!

Our optimized electrical heating system features high quality insulation and a stronger generator that significantly reduces heat-up times. The generator is driven by a flexible shaft from the gear box that offers great reliability and reduced maintenance. We are able to achieve even heat distribution thanks to our well-designed heating coils for bottom plates and tampers. Those opting for our gas heating system gets a remarkably shorter heat-up time and amazing pavement quality from the first stretch of track! Dynapac supports sustainable gas heating systems to reduce energy consumption as well as CO2 emissions.

ECCENTRIC FLEXILEVER

Dynapac´s unique Flexi Lever quickly and conveniently changes the angle of attack. This offers a visual control of screed settings to adopt various layer thicknesses during the paving process. Lever adjustment is made with a simple.

ERGONOMIC SIDE SHIELD CONTROL

The height and the angle of the side shield are adjustable with only one crank. The crank is placed on top of the side shield below the remote control, creating a comfortable, central workplace for the screed operator. Same central workplace we are also offering hydraulically moveable side shields. Brilliant light we are preseting with an integrated side shield light to ensure excellent paving results.

TECHNICAL FEATURES AND BENEFITS DURING PAVING

ERGONOMIC & COMFORTABLE DESIGN

Excellent and comfortable view to the hopper and all working areas due to the higher seat position and movable platform.

VARIO SPEED

Load sensing hydraulic system to reduce fuel consumption.

LOW NOISE

Large paver range reduced noise level to 104db(A) through an efficient drive concept, additional noise roof insulation and a noise optimized screed design.

MATERIAL TRANSFER

Unmatched capacity for reduced segregation & improved paving quality.

SAFE IMPACT SYSTEM

Hydraulic push rollers for reduced impact from trucks.

ALPHA TRACKS

More ground contact for better traction & improved life. Extra comfort with a movement via Remote Control 2.0 and the operator panel.

BRILLIANT LIGHT CONCEPT

Dynapac offers lighting systems for night work: LightAssist, LED lights, LED lighting balloons, auger & engine compartment lights as well as side and screed lights for wider working widths.

PAVEMANAGER 2.0 & REMOTE CONTROL 2.0

Intelligent control of the paver and the paving process for better quality.

STRONG AUGER

Slim auger drive with hydraulically adjustible height up to 25 cm. Dynapac offers auger diameters from 380-500 mm.

SAFE TRANSPORT

Hydraulically operated locking cylinders for the leveling arm and electric roof lifting. Safe, fast and easy!

DYNAPAC SCREED

Best in business with integrated leveling functions for excellent quality. The Flexilever offers fast and convenient change of the screed angle for different layer thicknesses.

MEETING OPERATORS NEED

EXCELLENT VISIBILITY

All round visibility! The operator has a clear view into the hopper, conveyor and auger compartment, as well as on the marker bar plus he has direct eye contact with screed operators and truck drivers. The comfortable platform slides out up to 500 mm on both sides just by pressing a button on the dashboard.

BRILLIANT LIGHT WITH LIGHTASSIST

Dynapacs LightAssist ensure more light, more visibilty, more safety! Coming home light and integrated side shield lights have been developed with the focus on operational efficiency. LightAssist especially supports applictions in dark times. Dynapacs operator appreciate our brilliant lighting concept.

ERGONOMIC WORK PLACE

In addition to effective compaction the Dynapac screed offers great accessibility. The low height gives you a superior view into the auger compartment and constant control over material flow. This low profile screed provides a central, safe and ergonomic workplace.

OPERATOR’S COMFORT

Our ergonomically designed cabin makes sure that the operator can work comfortably and effectively at all stages of the process. The platform offers generous head room and a flat floor with ample storage space. The big storage boxes in the floor of the platform improve the rear view. The plattform offers 2 integrated platform lights. The ergonomic comfort seats, also available with seat-heating, can be adjusted to any position you need. Repositioning the dashboard has become even easier with the improved dashboard console.

For a very fast paving start all automatic function for the paving are marked in yellow. The Dynapac SD paver generation also offers a weather house with opening side and front windows for comfortable operation in all weather conditions. To improve the working environment and keep the fume level around the operator stand low.

INTELLIGENT MANAGEMENT

PAVEMANAGER 2.0 & REMOTE CONTROL 2.0

Dynapac SD2500CS feature the updated PaveManager 2.0 control system that offers unmatched paving control for all applications from highway to city paving. This system ensures optimized paving performance again and again. Our high end integrated control system is intelligent and directly connected through a CAN-BUS system. This assures fast and reliable communication. Many changes and adjustments made on the Remote Control 2.0 can also be made from the dashboard and vice versa.

Dynapac Remote Control 2.0 is developed to recognizes all leveling equipment. They are self-configuring, meaning that you can use each one on either side. Both dashboard and remote controls offer color display and intuitive self-explanatory menus and functions. Symbols and pictures make handling even easier. Dynapac quick start functions on the dashboard & Remote Control 2.0 are marked in yellow to support operators.

REMOTE CONTROL 2.0

The software offers individual configuration. You select the parameters to be shown in the main view based on your needs.

AUTOMATIC PROGRAMMING

Automatic programing of slope and / or crowning for the paving distance.

MULTIFUNCTION

Allows you to track two parameters in one screen. The function can also be used as a crossover function where one screed operator can monitor and control both screed sides form one remote control.

MATERIAL CALCULATOR

This function calculates material paved and material to be paved. You simply enter the parameters of the job ahead of you and the program calculates how much material will be needed. Optional sensors give real-time input on screed width and layer thickness.

EXCELLENT PROCESS CONTROL

TRUCK DOCKING MADE EASY

Dynapac’s TruckAssist system is designed to help trucks dock correctly and safely with the paver by simplifying communication between the paver and truck driver. The system comprises two sturdy, LED bars which are strategically positioned on both hopper edges. TruckAssist allows safe, efficient communication between the drivers of the paver and the truck and also feeder driver. This enable the paver driver iwith a realtime display to remain in control of the truck docking process at all times. This feature is particularly useful in low noise areas, reducing the need to use the horn and guide the truck in dark times to the SD2500CS.

FAST, EASY REPOSITIONING WITH SETASSIST

SetAssist system is especially useful where there is a large amount of spot work involved as it is designed to reduce setting and transport times on the jobsite. Now the paver driver has the option to save the position of the auger and screed before moving from one section to the next. One push of a button on the redesigned operator panel will then lift the hydraulic front flap, auger and screed, lock the screed for transport and reverse the conveyor slightly. Other features, like our new electric track cleaner can be added on demand.

CLEANINGASSIST

Operators always in focus, we developed our supporting CleaningAssist. Pushing one bottom and several function moving slowly to make the cleaning work very easy. Operators are appreciating that function.

Dynapac tracked paver SD2500CS are powered by a Cummins QSB6.7 diesel engine with emission Stage IIIA / IV & V. The power unit offers optimized energy conversion through: load-sensitive engine speed control; use of the most efficient pumps and the most compact final drives, incl. motors. The cooling system is driven by a hydraulic motor that is thermostatically controlled for efficient cooling. The CAN-BUS system ensures high operational reliability and centralised control

VARIOSPEED

Optimal rpm at all times! VarioSpeed is a Dynapac patented drive concept that recognizes the required rpm for the specific working situation. A computer senses and controls the needed rpm, infinitely! This is an option that will save you money. It can save up to 15% on energy costs. Fuel consumption is reduced and the life of your engine is increased! This is a standard feature on SD 2550C / CS with Stage IV and V engines, others can be upgraded to VarioSpeed at any time.

ECOMODE

Dynapac EcoMode’s stepless operation makes it unique. You can adjust the engine rpm to suit the conditions of your particular job site. Instead of having a fixed rpm level, you individually set the level for the particular working situation in the eco-function. This function gives you lower fuel consumption, less noise and a longer life for your engine.

DYN@LINK

With the introduction of Dyn@Link, Dynapac Road Construction Equipment provides customers with a tool to monitor and manage their machine fleet efficiently and conveniently. The intelligent telematics system offers many possibilities to optimize fleet usage, to reduce maintenance costs and to save time and money.

3 Versions available

The new telematics Dyn@Link system is available in three versions: Dyn@Link, Dyn@Link Advanced and Dyn@Link Pro. All systems include the hardware with sim-card, webpage access and a 36-month data connection package, which can be extended after 3 years

All machines, together with important information such as position, fuel and Ad-blue levels, service status and map view, are listed on the dashboard. Thanks to the online portal and the Dyn@Link app, users can access this information from anywhere and at any time. Customize the tool for your needs The user-friendly webpage is easy to learn and the various filters and personal setting options for graphs and tables allow you to adapt the webpage to your individual requirements.

MAINTENANCE

CONTROL YOUR COSTS

Being active in the Road Construction business requires considerable investment. Every square meter involves an operational cost composed of fixed costs such as interest on equipment acquired, labor costs, insurance and equipment depreciation, but also variable costs such as expenses for fuel, wear and maintenance.

Wear cost

Since Dynapac paver always uses high-quality wear parts, the time that is needed to change them can be kept to a minimum. Customers who use Dynapac spare parts will improve reliability and protect their investment.

Operator cost

The operator is always a very big part of the total cost. Operators using Dynapac equipment will enjoy good ergonomics and easy-to-operate equipment.

Maintenance cost

All road construction equipment need regular check-ups such as change of oils and filters. Dynapac always strives to use components that require as little maintenance as possible.

Investment cost

The purchase price is often only a relatively small part of the total cost. Dynapac rollers and pavers maintain a high value throughout their working life, which is good to know if you ever want to sell it

Fuel cost

Fuel expenses can make up a large part of your total cost. Since Dynapac rollers and pavers are equipped with a very efficient hydraulic system, your fuel cost can be kept at a low level.

REGULAR MAINTENANCE PREVENTS COSTLY STANDSTILLS.

Equipment breakdowns have a direct impact on your productivity. No production means no revenue, but the fixed costs stay the same, resulting in lower profitability. By avoiding breakdowns and increasing the reliability of your machine, you will be able to produce more per year, which will immediately improve your profitability.

PREVENTIVE MAINTENANCE KITS

All in one box and tailored to match your equipment. Easy to obtain and attractively priced, our preventive maintenance kits contain all the parts required for the equipment’s scheduled maintenance program. When installed by one of our certified technicians, you keep equipment downtime to a minimum and its uptime to a maximum throughout its working life.

PREVENTIVE MAINTENANCE PAYS BACK

Equipment needs preventive maintenance that demands

- Timely intervention to avoid expensive breakdowns.

- High quality maintenance also means higher resale value (residual value)