-

Your shopping cart is empty!

Slipform paver Wirtgen SP 94

Offset pavers are used to produce monolithic concrete profiles such as protective concrete walls, kerb profiles, gutters or narrow paths. Thanks to numerous options, such as for concrete feeding or slipforming, offset slipform pavers are extremely versatile. Inset pavers cost-effectively produce concrete pavements, such as for motorways, arterial roads, runways or railway lines. In addition to single-layer concrete paving, bottom-layer and top-layer concrete can also be paved synchronously in two layers ‘wet on wet’.

Offset slipform pavers

With offset slipform pavers, the concrete is transported into the offset mold via a loading conveyor or a conveyor auger. The offset mold can be mounted on the left or right-hand side of the machine. A number of molds in a wide range of different shapes and sizes are available for individual applications. The offset profiles are continually produced monolithically, with or without reinforcements. Machine features include a top-quality machine control system, a practical steering and drive system and stringline-free concrete paving.

Inset slipform pavers

With inset slipform pavers, the concrete is placed directly in front of the machine and distributed by a spreading auger or spreading plough. Vibrators compact the concrete homogeneously and the mold forms it in the specified width and thickness as the slipform paver advances. Integrated dowel bar and tie bar inserters position dowel bars and tie bars as specified. The finishing beam levels the area transverse to the pavement and the super smoother creates a perfect surface. When paving dual-layer concrete, the bottom-layer and top-layer concrete are processed simultaneously and paved wet-in-wet.

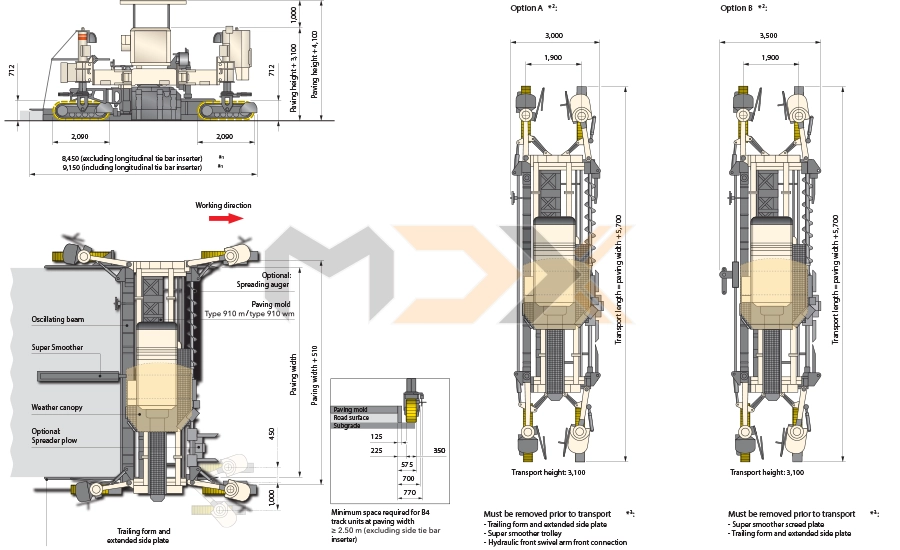

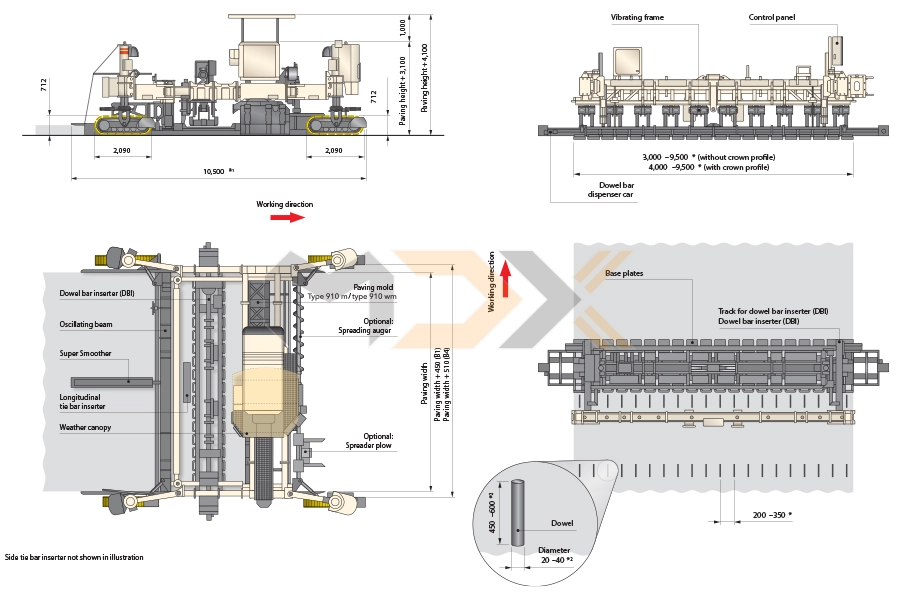

| Dimensions | ||

|

||

|

||

| Paving situation: SP 94i / SP 94 slipform pavers equipped with spreading auger or spreading plow, type 910 m/type 910 wm paving mold, oscillating beam and super smoother | ||

|

||

| Transport situation: SP 94 / SP 94i slipform pavers equipped with spreading auger or spreading plow, type 910 m/type 910 wm paving mold, oscillating beam and super smoother | ||

| Range of applications | ||

| Road surface application without crown profile |

m | Paving width: 2.00 to 9.50 m*1 |

| mm | Paving height: up to 450 mm*1 | |

| Road surface application with crown profile | m | Paving width: 3.50 to 9.50 m*1 |

| mm | Paving height: up to 450 mm*1 | |

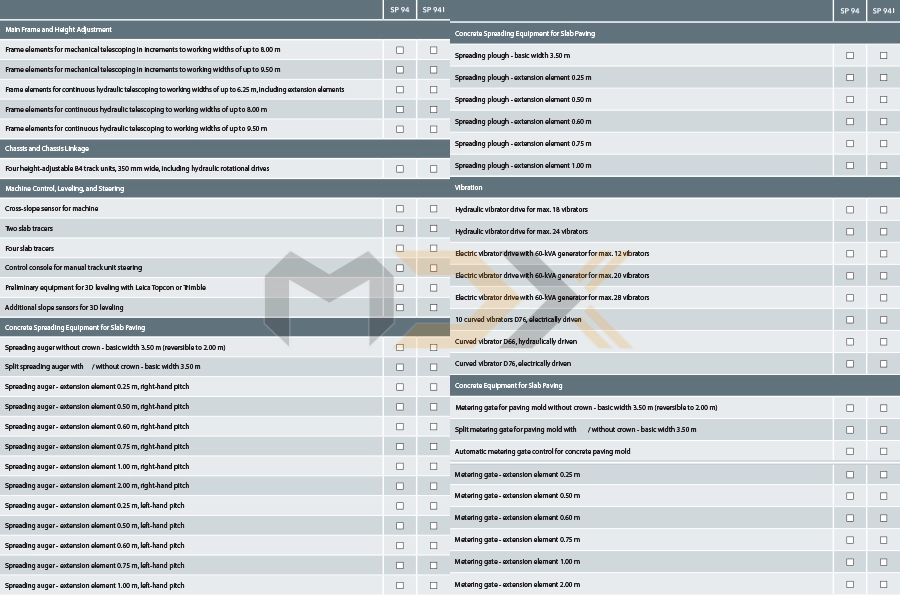

| Concrete spreading equipment | ||

| Spreading auger | m |

One-piece, modularly extendable up to 9.50 m Two-piece, modularly extendable up to 9.50 m |

| Spreader plow | m | Modularly extendable up to 9.5 m |

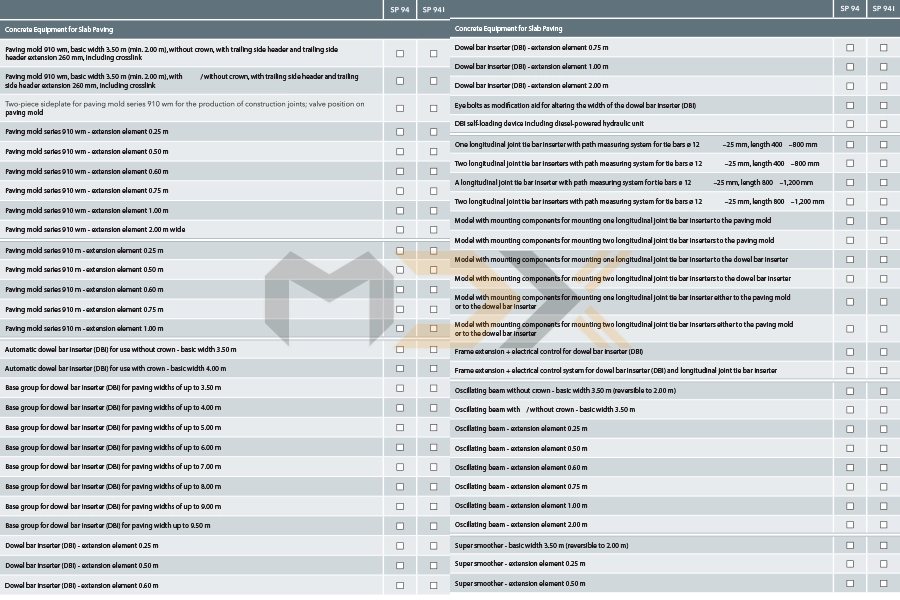

| Slab paving equipment | ||

| Type 910 m paving mold (without wear sole, without crown profle function) | m | Modularly extendable up to 9.5 m |

| Type 910 wm paving mold (with wear sole, with or without crown profle function) | m | Modularly extendable up to 9.5 m |

| Dowel bar inserter (DBI) | m | Modularly extendable up to 9.5 m |

| Oscillating beam | m | Modularly extendable up to 9.5 m |

| Super smoother | m | Modularly extendable up to 9.5 m |

| Longitudinal tie bar inserter | 1 or 2 | |

| Side tie bar inserter | m | Bên phải và / hoặc bên trái |

| Vibrators and circuits | ||

| Hydraulic vibration | 12 connectors (optional: 18 or 24 connectors) | |

| Electric vibration | 12 connectors (optional: 20 or 28 connectors) | |

| Hydraulically driven vibrators | Curved (D66) | |

| Electrically driven vibrators | Curved (D76) | |

| Engine | ||

| Engine manufacturer | Cummins | |

| Type | QSC8.3 C-300 | |

| Cooling | Water | |

| Number of cylinders | 6 | |

| Rated power at 2,100 rpm | kW / HP / PS | 224 kW / 300 HP / 305 PS |

| Displacement | cm3 | 8 300 cm3 |

| Fuel consumption, full load | 2/3 load | L / h | 61.8 l/h | 41.2 l/h |

| Sound power level in accordance with DIN EN 500-2 engine | operator’s platform | dB(A) | ≤ 102 dB(A) | ≥ 80 dB(A) |

| Exhaust emission standards | EU Stage 3a / US Tier 3 | |

| Electrical system | ||

| Voltage supply | 24 V DC | |

| Electric vibration | 110 V AC 3 ~ / 200 Hz | |

| Filling capacities | ||

| Fuel | L | 500 |

| AdBlue®/DEF*3 | L | - |

| Hydraulic oil, electric vibration | L | 250 |

| Hydraulic oil, hydraulic vibration | L | 380 |

| Water | L | 550 + 550 |

| Driving performance | ||

| Operating speed | m / min | 0 - 7 |

| Travel speed | m / min | 0 - 22 |

| Crawler Units | ||

| Number | 4 | |

| Type B4: Dimensions (L x W x H) | mm | 2 090 x 350 x 726 |

| Height adjustment of machine | ||

| Hydraulic | mm | 1 000 |

| Mechanical | mm | 153 |

| Crown | ||

| Variable adjustment range |

At paving widths of 3.50 to 8.00 m: max. 3%*3 At paving widths of 8.00 to 9.50 m: max. 2%*3 |

|

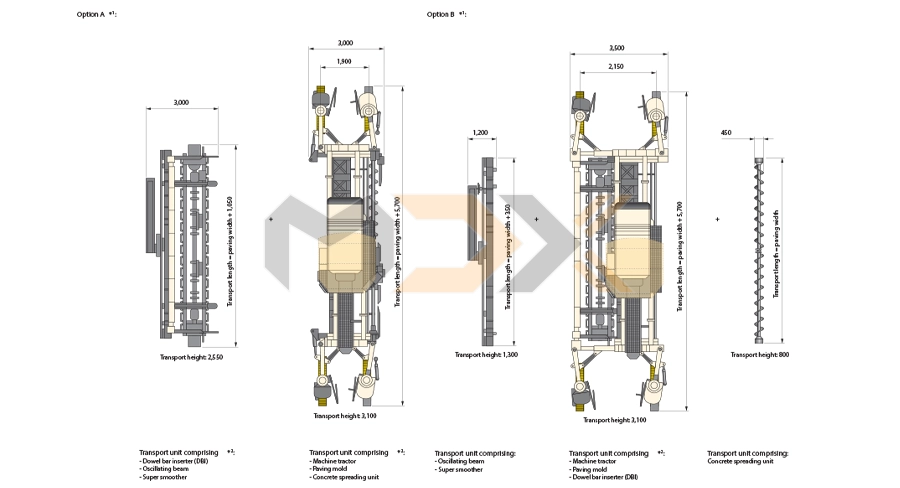

| Transport dimensions (L x W x H) | ||

| Paving width 3.50 m: Machine including type 910 m/type 910 wm paving mold, with spreader plow, oscillating beam, super smoother | mm | 9 200 x 3 000 x 3 100 |

| Paving width 9.50 m: Machine including type 910 m/type 910 wm paving mold, with spreader plow, oscillating beam, super smoother | mm | 15 200 x 3 000 x 3 100 |

| Weight Specifcations | ||

| Operating weight CE*4 (with type 910 m paving mold), 3.50 m | kg | 26 020 |

| Machine weight*5 | kg | 24 000 - 65 000 |

*1 = Special paving widths, paving heights, and options available on request

*2 = AdBlue® is a registered trademark of the German Association of the Automotive Industry (VDA)

*3 = Values within standard transport height; special dimensions on request

*4 = Machine weight, half-full tanks, vehicle tool kits, machine operator (75 kg), excluding optional equipment

*5 = Weight specifications depend on the installed equipment and paving width

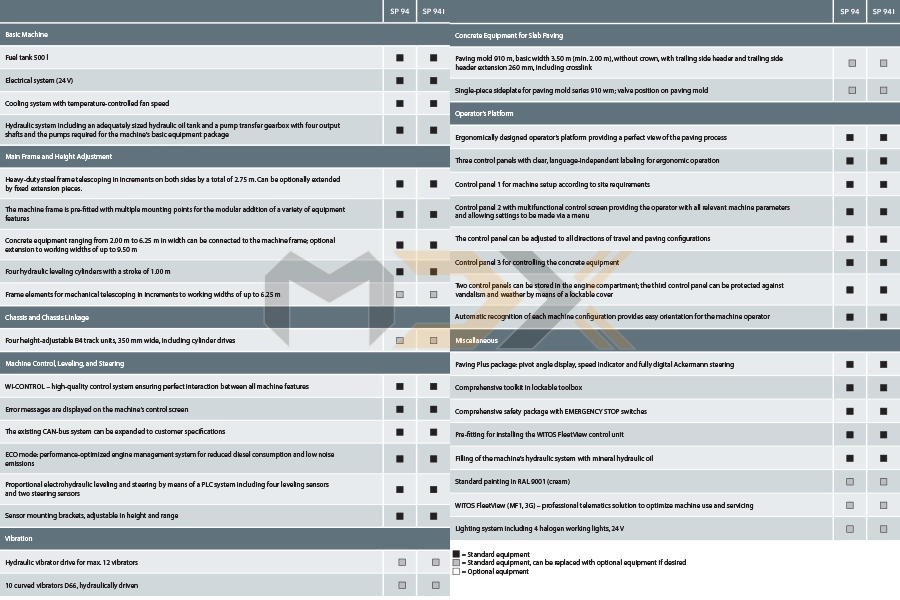

1. RUGGED MACHINE DESIGN

The machine’s rugged design guarantees consistent, high-output concrete paving and precise paving results, even under difficult site conditions

2. FULLY MODULAR MACHINE DESIGN

The machine’s fully modular design means its possible to flexibly modify, upgrade with new options, and adapt the machine to the specific job site situation.

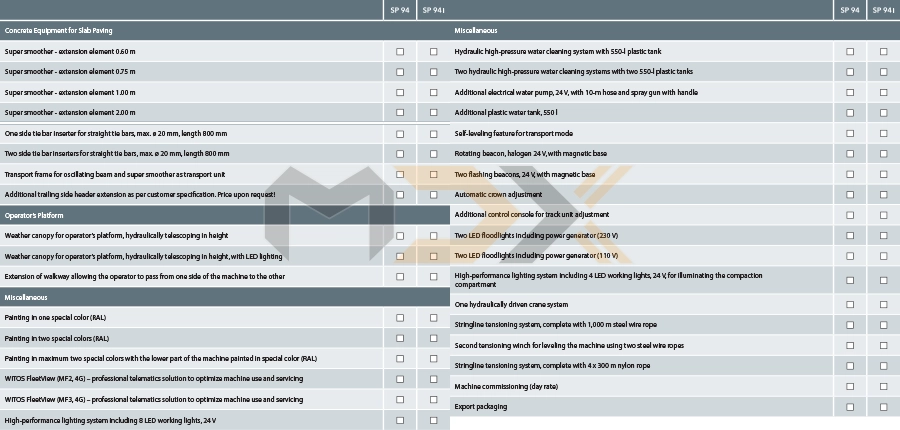

3. SOPHISTICATED TRANSPORT CONCEPT

Compact dimensions and minimal time and effort needed to prepare the machine make loading easy and transport cost-effective. Depending on the configuration, the dowel bar inserter or oscillating beam, super smoother, and concrete spreader can remain mounted to the machine during transport.

4. HIGHLY FLEXIBLE CONCRETE PAVING

The standard version of the slipform paver is capable of paving perfect and precise concrete surfaces from 3.5 m to 9.5 m wide and up to 450 mm thick.

5. TRIED-AND-TESTED PAVING MOLD

Compatible with the 910 m or 910 wm series of metric inset paving molds. The 910 wm series comes standard with a wear sole and an be equipped with an optional crown profile.

6. REINFORCEMENT INSERTION BUILT INTO THE MACHINE

A self-loading dowel bar inserter, tie bar inserter(s), and side tie bar inserter(s) are available on request.

7. ALTERNATIVE COMPACTION TECHNOLOGY

Depending on site requirements, the machine can be equipped with a hydraulic or electric vibrator drive. The machines comes standard with 12 hydraulic connections (optional: 18 or 24), with 12, 20, or 28 electrical connections optional.

8. COST-EFFECTIVE ENGINE MANAGEMENT

The “ECO Mode” setting automatically adjusts engine power to the current performance requirements to ensure fuel-efficient diesel consumption and low noise emissions

9. STATE-OF-THE-ART ENGINE TECHNOLOGY

Wirtgen SP 94 features cutting-edge, high-performance engine technology (224 kW/300 HP/304 PS) that meets EU Stage IIIa/ US EPA Tier 3 emissions standards. The SP 94i features cutting-edge, high-performance engine technology (231 kW/310 HP/314 PS) that meets EU Stage IV/US EPA Tier 4f emissions standards

10. PERFECT ERGONOMICS AND HANDLING

The ergonomically designed operator’s platform, the standardized, intuitive operating concept for all SP series’ models, and exceptional visibility makes the job easier for the operator.

11. HIGH-PRECISION STEERING AND DRIVE SYSTEMS

Intelligent steering and control systems for extremely smooth operation – even around tight curves – make high-precision concrete paving possible.

12. PRODUCTIVITY-ENHANCING STEERING

Numerous optional and standard steering features, like hydraulic swivel arms and the innovative worm gear steering, significantly increase site productivity

13. MACHINE CONTROL SYSTEMS FEATURING ADVANCED INTELLIGENCE

WIRTGEN’s efficient WITOS FleetView telematics system supports fleet management, position and status monitoring, as well as maintenance and diagnostic processes.

14. PRODUCTIVITY-ENHANCING STEERING

The field-proven interface guarantees tested compatibility with leading suppliers’ 3D control systems.

Tags: Wirtgen SP 15, slipform paver for sale, slipform paver Wirtgen, slipform paver machine, slipform paver price, slipform paver sp 1200, slipform paver sp 500, wirtgen slipform paver, trailrider slipform paver, wirtgen slipform paver sp 1600 price, wirtgen sp500 slipform paver, wirtgen sp 15 slipform paver, concrete slipform paver, gomaco slipform paver, sidewalk slipform paver, mbw slipform paver for sale, wirtgen slipform paver sp 1600, slipform concrete paver, slipform barrier paver, slipform curb paver, slipform sidewalk paver