-

Your shopping cart is empty!

Slipform paver Wirtgen SP 62

Offset pavers are used to produce monolithic concrete profiles such as protective concrete walls, kerb profiles, gutters or narrow paths. Thanks to numerous options, such as for concrete feeding or slipforming, offset slipform pavers are extremely versatile. Inset pavers cost-effectively produce concrete pavements, such as for motorways, arterial roads, runways or railway lines. In addition to single-layer concrete paving, bottom-layer and top-layer concrete can also be paved synchronously in two layers ‘wet on wet’.

Offset slipform pavers

With offset slipform pavers, the concrete is transported into the offset mold via a loading conveyor or a conveyor auger. The offset mold can be mounted on the left or right-hand side of the machine. A number of molds in a wide range of different shapes and sizes are available for individual applications. The offset profiles are continually produced monolithically, with or without reinforcements. Machine features include a top-quality machine control system, a practical steering and drive system and stringline-free concrete paving.

Inset slipform pavers

With inset slipform pavers, the concrete is placed directly in front of the machine and distributed by a spreading auger or spreading plough. Vibrators compact the concrete homogeneously and the mold forms it in the specified width and thickness as the slipform paver advances. Integrated dowel bar and tie bar inserters position dowel bars and tie bars as specified. The finishing beam levels the area transverse to the pavement and the super smoother creates a perfect surface. When paving dual-layer concrete, the bottom-layer and top-layer concrete are processed simultaneously and paved wet-in-wet.

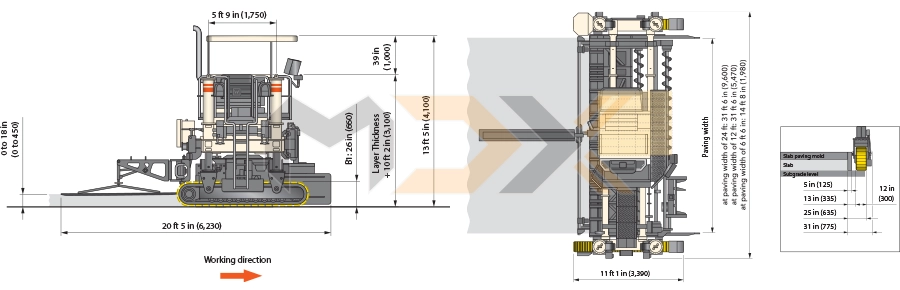

| Dimensions | ||

|

||

| Paving situation: Slipform paver SP 62 / SP 62i equipped with spreading auger or spreading plough, slab paving mould type 910 m/type 910 wm, oscillating beam and super smoother | ||

|

||

| Transport situation: SP 62 / SP 62i equipped with spreading auger or spreading plough, slab paving mould type 910 m/type 910 wm, oscillating beam and super smoother | ||

| Range of applications | ||

| Slab paving application |

m | Paving width: 3.50 m to 7.50 m*1 |

| mm | Layer thickness: up to 450 mm*1 | |

| Concrete spreading equipment | ||

| Spreading auger | m |

Single-piece auger, nới rộng được lên đến 6 m Two-piece auger, nới rộng được lên đến 7.5 m |

| Spreading plough | m | Modular extension to up to 7.50 m |

| Slab paving equipment | ||

| Slab paving mould type 910 m (without wearing pan, without crown feature) | m | Modular extension to up to 7.50 m |

| Slab paving mould type 910 wm (with wearing pan, with or without crown feature) | m | Modular extension to up to 7.5 m |

| Oscillating beam | m | Modular extension to up to 7.5 m |

| Super smoother | m | Modular extension to up to 7.5 m |

| Side tie bar inserter | m | Bên phải và / hoặc bên trái |

| Vibrators and circuits | ||

| Hydraulic vibration | 12 connectors (optional: 18 connectors) | |

| Electric vibration | 18 connectors (optional: 24 connectors) | |

| Hydraulically driven vibrators | Curved (D66) | |

| Electrically driven vibrators | Curved (D76) | |

| Engine | ||

| Engine manufacturer | Deutz | |

| Type | TCD 2012 L06 2V | |

| Cooling | Bằng nước | |

| Number of cylinders | 6 | |

| Rated power at 2,300 rpm | kW / HP / PS | 155 kW / 208 HP / 211 PS |

| Displacement | cm3 | 6 057 cm3 |

| Fuel consumption, full load | L / h | 42 |

| Fuel consumption, 2/3 load | L / h | 17 |

| Exhaust emission standards | EU Stage 3a / US Tier 3 | |

| Electrical system | ||

| Voltage supply | 24 V DC | |

| Electric vibration | 110 V AC 3 ~ / 200 Hz | |

| Filling capacities | ||

| Fuel | L | 400 |

| AdBlue®/DEF*3 | L | - |

| Hydraulic oil, electric vibration | L | 200 |

| Hydraulic oil, hydraulic vibration | L | 400 |

| Water | L | 500 + 500 |

| Driving performance | ||

| Operating speed | m / min | 0 - 6 |

| Travel speed | m / min | 0 - 18 |

| Track units | ||

| Number | 2 | |

| Type B1: Dimensions (L x W x H) | mm | 3 390 x 300 x 660 |

| Height adjustment of machine | ||

| Hydraulic | mm | 1 100 |

| Mechanical | mm | 420 |

| Crown | ||

| Variable adjustment range | For paving widths from 3.50 m to 7.50 m: max. 3 %*3 | |

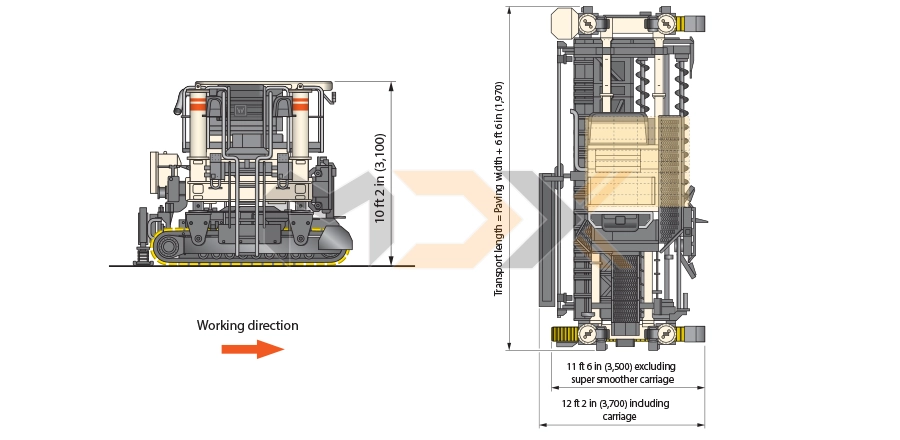

| Transport dimensions (L x W x H) | ||

| Paving width 3.50 m: Machine with slab paving mould type 910 m/type 910 wm, including spreading plough, oscillating beam and super smoother (without super smoother carriage) | 5,750 x 3,500 x 3,100 mm | |

| Paving width 7.50 m: Machine with slab paving mould type 910 m/type 910 wm, including spreading plough, oscillating beam and super smoother (without super smoother carriage) | 9,750 x 3,500 x 3,100 mm | |

| Machine weights | ||

| Operating weight, CE*4 (with slab paving mould type 910 m), 3.50 m | kg | 25 000 |

| Machine weight*5 | kg | 24 000 - 34 000 |

*1 = Please consult factory for special paving widths, layer thicknesses and optional equipment features

*2 = AdBlue® is a registered trademark of the Association of the Automotive Industry (Verband der Automobilindustrie e. V.; VDA)

*3 = Values within standard transport height; please consult factory for special dimensions

*4 = Weight of machine, half weight of all operating materials, on-board tools, machine operator (75 kg), no optional equipment features

*5 = Weights depend on the paver’s range of equipment and paving width

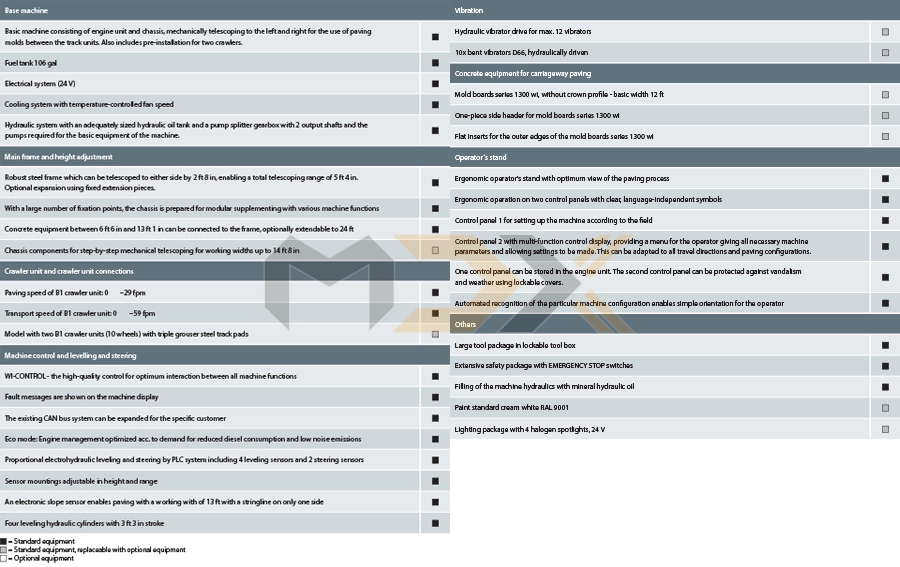

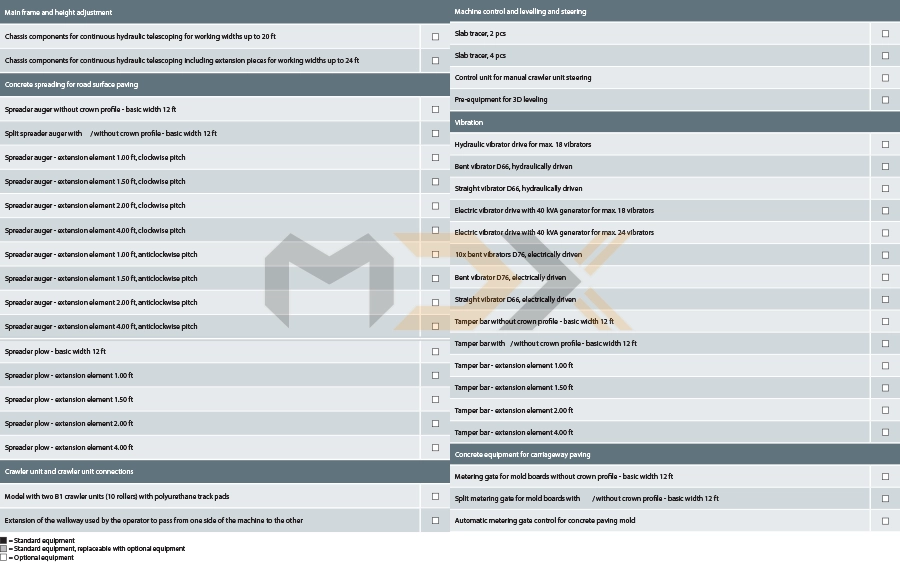

1. FULLY MODULAR MACHINE LAYOUT

The paver’s fully modular design is synonymous with flexible modification, easy retrofitting of optional equipment features and application-specific adjustment to site conditions

2. INTELLIGENT TRANSPORT CONCEPT

Compact dimensions and the two-track design of máy trải bê tông Wirtgen SP 62 ensure ease of transport as well as quick setup and operational readiness. Oscillating beam, super smoother and concrete spreading equipment can remain mounted on the machine during transport.

3. EXCEPTIONAL FLEXIBILITY IN CONCRETE PAVING

Slipform paver 62 achieves perfection in the highly precise paving of standard concrete slabs at widths ranging from 3.5 m to 7.5 m and layer thicknesses of up to 450 mm.

4. PROVEN SLAB PAVING MOULD

Customers can choose between 910 m series or 910 wm series metric inset slab paving moulds. The 910 wm series mould comes with wearing pan as standard and crown as an optional feature.

5. MACHINE-INTEGRATED INSERTION OF STEEL REINFORCEMENT

A tie bar inserter in front of the slab paving mould and side tie bar inserter(s) are available in accordance with customer requirements

6. ALTERNATIVE COMPACTION TECHNOLOGY

The machine can be equipped with a hydraulic or electric vibrator drive to comply with site requirements. It comes with 12 hydraulic connectors in standard design (optionally 18) but can optionally be fitted with 18 or 24 electric connectors.

7. EFFICIENT ENGINE MANAGEMENT

The ECO mode feature automatically adjusts the engine output to current performance requirements, thus ensuring diesel efficiency and low noise emissions.

8. STATE-OF-THE-ART ENGINE TECHNOLOGY

Wirtgen SP 62 features state-of-the-art, high-performance engine technology (max. 155 kW/208 HP/211 PS) complying with exhaust emission standards EU Stage IIIa/US Tier 3. The SP 62i features state-of-the-art, high-performance engine technology (max. 180 kW/241 HP/245 PS) complying with exhaust emission standards EU Stage IV/US Tier 4f

9. PERFECTION IN ERGONOMIC DESIGN AND HANDLING

Relaxed working is ensured by the ergonomically designed workplace offering perfect visibility and an intuitive operating concept standardized for all SP model ranges.

10. HIGH-PRECISION STEERING AND DRIVE SYSTEMS

Intelligent control systems for exceedingly smooth operation and the highly responsive skid steering system ensure precision in concrete paving.

11. MACHINE CONTROL SYSTEMS WITH ADVANCED INTELLIGENC

The efficient WIRTGEN WITOS FleetView telematics system supports fleet management, machine position and status monitoring, as well as maintenance and diagnostic procedures

12. FIELD-PROVEN 3D INTERFACE

The field-proven interface guarantees tested compatibility with the 3D control systems of leading suppliers.

Tags: Wirtgen SP 62, slipform paver for sale, slipform paver Wirtgen, slipform paver machine, slipform paver price, slipform paver sp 1200, slipform paver sp 500, wirtgen slipform paver, trailrider slipform paver, wirtgen slipform paver sp 1600 price, wirtgen sp500 slipform paver, wirtgen sp 15 slipform paver, concrete slipform paver, gomaco slipform paver, sidewalk slipform paver, mbw slipform paver for sale, wirtgen slipform paver sp 1600, slipform concrete paver, slipform barrier paver, slipform curb paver, slipform sidewalk paver